CASE STORY

Scan Sverige

A new vision system provides extra security and is expected to pay for itself within the first year in production

At Scan Sverige AB in Linköping, a large variety of sausages are produced, including ”falukorv”, chorizo, kabanoss, skinless sausage, hot dogs, and even the classic ”Bullens pilsner sausage”.

Recently, a new vision system from TriVision was installed here to further ensure that the sausage is completely free from foreign particles. We talked to Johan Larsson that works as a production coordinator to discuss the new system.

As you can read from the short interview below, he was very pleased with the new system, among other reasons, because it provides extra product security and is expected to pay for itself within the first year in production.

Ensuring our raw materials are free from plastic

Ideally, we don't want to find anything, but when we do, it’s a real reassurance that the machine does its job and ensures our raw materials are free from plastic.

Johan Larsson

Production Coordinator, Scan Sverige AB, Linköping

What was the reason for investing in the vision system?

- In the food industry, we are always looking for new ways to secure every part of the production, all the time. It's so easy during cutting or from external suppliers, for a plastic bag or something else that shouldn't be there to get into our system with the meat, and that contaminates a lot of raw materials.

Is the reduction of waste the most important benefit of the system?

- Yes, you could say that since the loss of raw materials is also associated with very high costs. When TriVision’s system can find pieces of plastic that are 5 x 5 mm and larger, we can save a lot of raw materials from being simply thrown away.

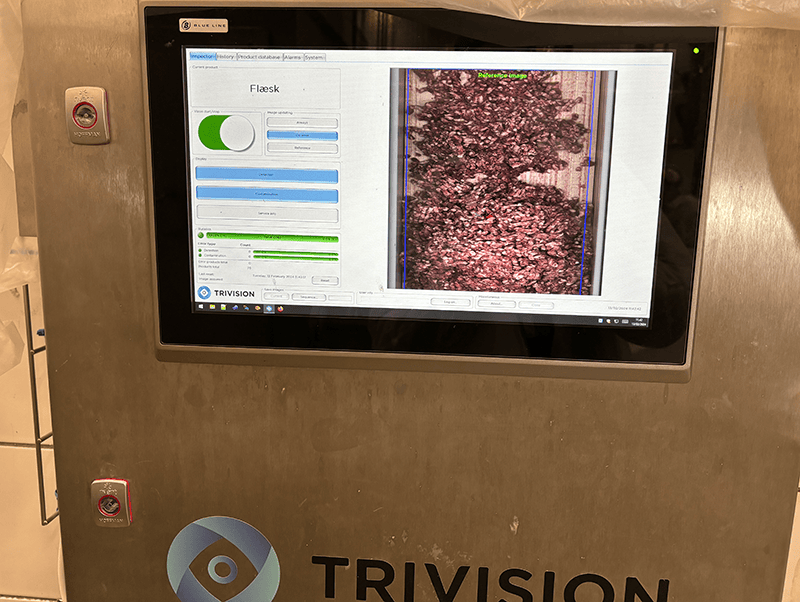

More about the vision system

The vision system consists of an advanced camera placed about two meters from the conveyor after the actual grinder. Lights illuminate the area that the camera scans. When the system detects an anomaly, both the belt and grinder stop, and an alarm on the screen informs about what has been detected.

- It's an easy-to-operate system once it's installed, just press a button and let the system do its job, says Johan Larsson

Was it a good investment to purchase and install the system?

- Yes, it was a good investment. We estimate that it has paid for itself after the first year in operation, which must be considered a good investment. It fulfills the purpose of securing our products. It hasn't been running for long, and it has only stopped the system once, but just that incident has already saved a lot. Costs during downtime always depend on how much raw material we must throw away, says Johan Larsson, concluding:

- Ideally, we don't want to find anything, but when we do, it’s a real reassurance that the machine does its job and ensures our raw materials are free from plastic.