Quality Assurance

ENSURE COMPLIANCE AND FOOD SAFETY

Achieve Perfection in Quality and Documentation

Food manufacturers face an enormous responsibility and increasingly demanding requirements when it comes to complying with legislations to ensure food safety.

TriVision vision systems are accurate, reliable solutions based on leading vision technology that ensure all the approved products' quality and compliance with legislations, protecting consumers from potential food hazards and brands from damaging recalls. Complete documentation of all inspections and product approvals serve as indisputable proof of complete compliance with legislations.

To ensure food safety and comply with legislations, TriVision solutions are used to reject all products with e.g. spoiled food, foreign objects in surfaces, compromised package seals and incorrect food labelling and date markings.

CONSISTENT QUALITY LEVEL

Meet and Exceed Expectations of Consumers and Retailers

Reliable inspection and failure detection not only ensure compliance, food safety and an efficient production, but also a consistent quality level in food products and hence the same customer experience in every product. By creating consistency in product quality and hence the product offering, TriVision solutions help food producers earn and maintain loyal customers.

With a consistent product quality and the possibility of complete documentation, manufacturers are also able to meet and exceed the needs of retailers with the most stringent requirements for product quality and quality control.

How Machine Vision Turns Quality Assurance Profitable

Quality assurance is an important process for food manufacturers as it protects brand reputation, sales, and profits. From recalls, fines and sales decline – all potential outcomes if defective products leave the factory.

But even though being perceived as an important process, quality assurance is also perceived as a cost. A cost that does minimize the risk of facing additional costs – but still a cost. And hopefully, it is a cost that can be reduced over time while maintaining the same level of product quality and protection of brand reputation, sales, and profits.

But what if your quality assurance could be more than just a cost needed to maintain an economic status quo? What if your next quality assurance solution also could be an efficient production optimisation tool and a profitable investment?

At TriVision, we have utilized the strengths of our leading machine vision technology to make quality assurance a profitable business case for manufacturers.

The path towards turning your quality assurance into a truly profitable investment starts with understanding how TriVision systems create value for manufacturers.

Think of a TriVision Vision system not only as an effective quality control system for Quality Managers, but also as an efficient production optimization tool for both Operators and Production Managers.

Make Quality Assurance Profitable

Discover how TriVision systems significantly improve your OEE

Our vision solutions contain unique features that significantly enhance manufacturers’ business performance. They do so by ensuring quality while reducing quality assurance costs and enabling substantial production optimization.

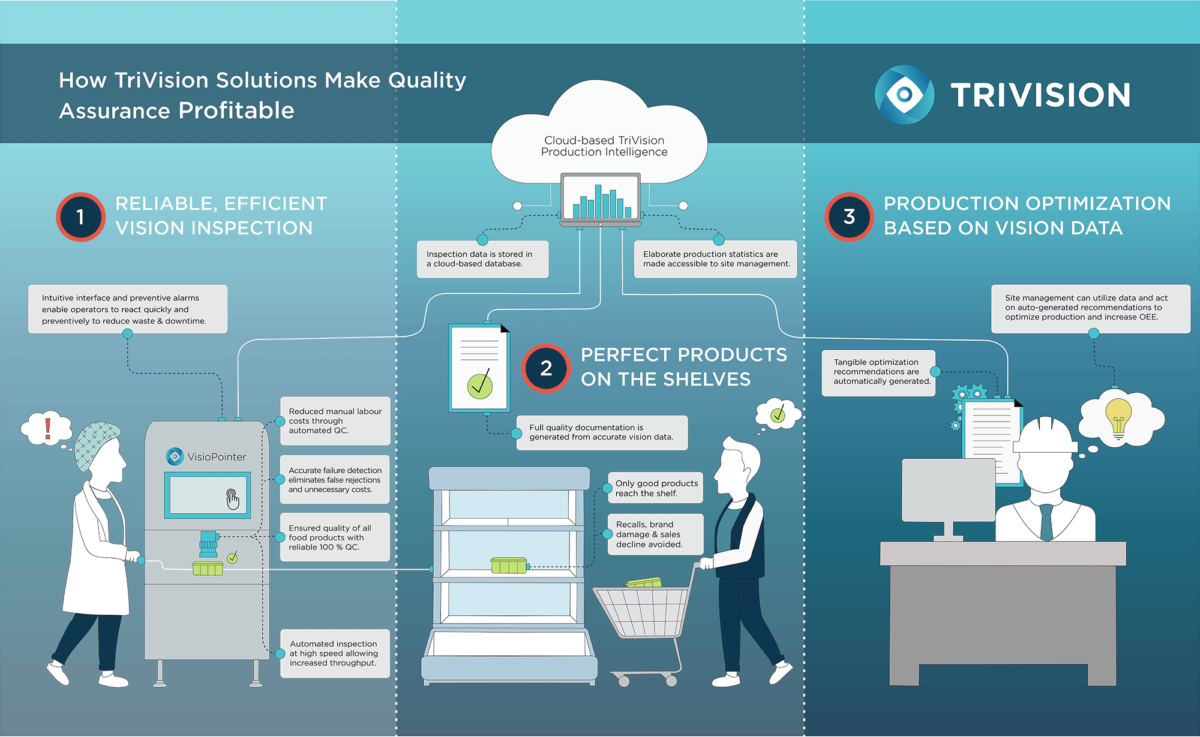

Dive into our infographic to discover how a TriVision solution makes quality assurance profitable.

1. Reduce QC costs, unnecessary waste and increase throughput

Efficient, reliable vision inspection

Some of the most obvious costs that our automated inspection reduces are manual labour costs. Based on leading vision technology build on highly advanced algorithms, TriVision systems can reliably perform accurate quality control of all products in high speed productions and hereby release manual labour resources from tasks that increasingly challenge the human eye.

The accurate failure detection eliminates all falsely rejected products. With the ability to set up and accurately follow thresholds for all error types, TriVision systems will only detect and reject products with variations that actually are defined as defective products. As a result, unnecessary food loss, waste and costs will be avoided.

As our automated vision-based quality control can inspect products at high speed, multiple packages per second, operators can maximize the speed of their conveyor belt and overall production to increase throughput and hence OEE while still ensuring complete quality assurance.

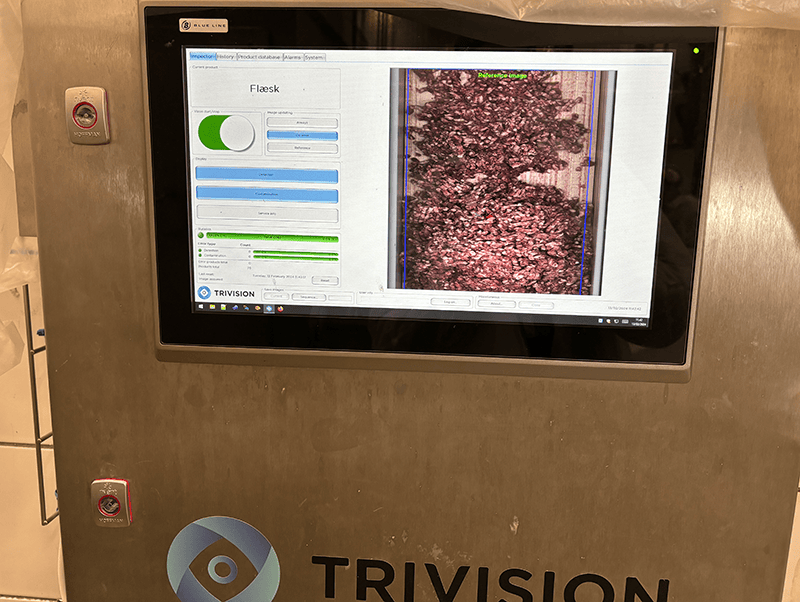

A user-friendly system for operators to minimize costs

We have made sure that operators on the shop floor easily can utilize all the valuable data that TriVision systems generate when inspecting each product. The system brings a clear overview of production performance and error distribution with real-time data and sets off immediate alarms if an unacceptable number of defective products appear.

Preventive alarms can also be set up to spot and predict specific tendencies in the production, e.g. if label placement worsens. Based on inspection data and advanced mathematical models, the system can spot and predict if a tendency of e.g. slightly tilted label placements, but still acceptable placements, will worsen and result in unacceptable label placements. If an issue is predicted, the system can preventively alert the operator. This enables the operator to take preventive actions in terms of making adjustments or planning maintenance, before the tendency turns into unacceptable errors that cause food loss, waste, and unplanned stops.

Hence, the preventive alarms improves OEE significantly by reducing food loss, waste and converting unplanned stops into planned maintenance.

2. Avoid expensive recalls and sales decline

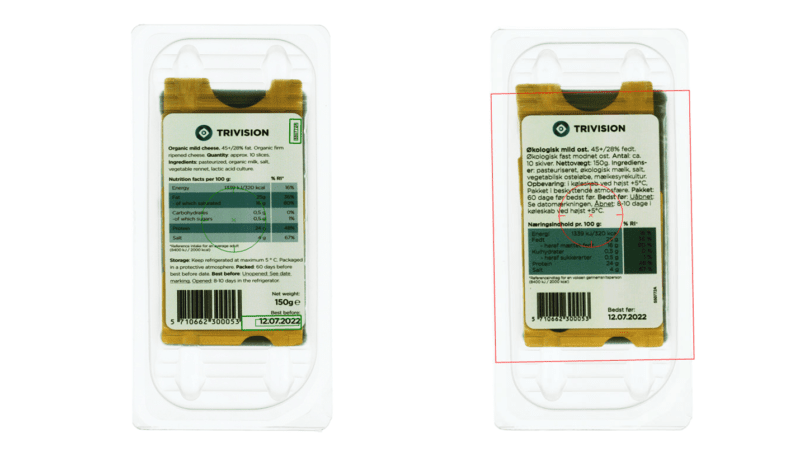

The purpose of quality assurance within the food industry is first and foremost to ensure the quality of products that leave the factory to reach supermarket shelves. Whereas quality assurance based on manual labour minimizes the risk of sending out defective food products and packaging, a TriVision system eliminates that risk with reliable inspection of all products and full product quality documentation. A risk that is worth eliminating, as errors in package seals, labels, date markings or appearance can cause bad customer experiences, sales decline, recalls, fines from retailers and in worst case food safety hazards.

Even if manufacturers would choose to reduce conveyor belt speed and decrease productivity to allow manual labour inspection of all products, humans are expected to make mistakes at some point. The number of defective products that will slip through annually and its consequences will vary for each manufacturer.

However, our experiences show us that a TriVision solution is a good business case for most manufacturers using manual labour inspection based solely on how our solution can eliminate the annual average costs of recalls and fines.

3. An efficient production optimization tool based on vision data

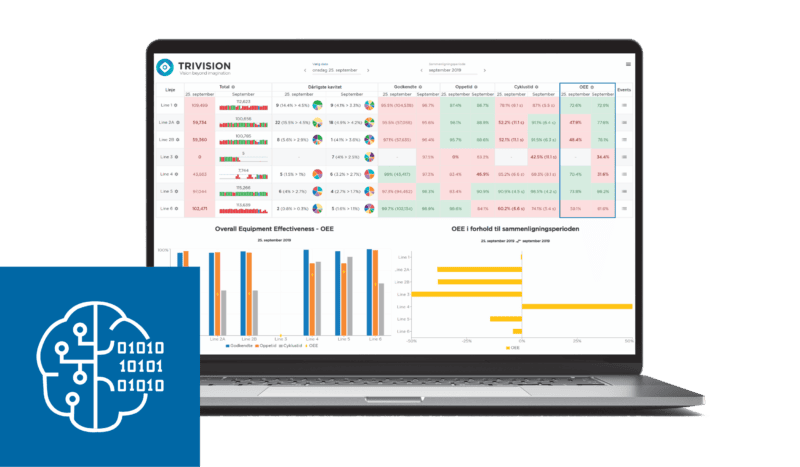

Additionally, manufacturers can utilize the generated inspection data further to perform production optimization. Data is generated from all inspections and is converted into elaborate production statistics in TriVision’s cloud-based Production Intelligence data base. As the production statistics are based on accurate vision data, Production Managers can get true, valuable insights into statistics on the overall OEE, uptime, rejected products, error type distribution and cavity error distribution. It allows them to potentially spot trends across various process parameters such as material suppliers or work shifts.

Based on the historic inspection data, our intelligent algorithms and mathematical models, TriVision’s Production Intelligence solutions automatically generate tangible recommendations based on these inspection data, which support managers in spotting the production trends that are profitable to change. Hence, with a TriVision system, site management can always count on having concrete suggestions for optimizing their production.

Knowledge Center

Ensure Quality with TriVision's

Label & Seal Inspection Combined

TriVision's unique combination

In the fast-paced world of the food industry, ensuring the quality and safety of your products is paramount. As of today, food manufacturers normally operate several different types of equipment to manage quality control of both sealing of the products as well as to ensure correct labeling of the packages.

Our advanced vision technology provides a comprehensive solution for food companies looking to guarantee the integrity of both their food products and packaging.

Benefits with our unique combination

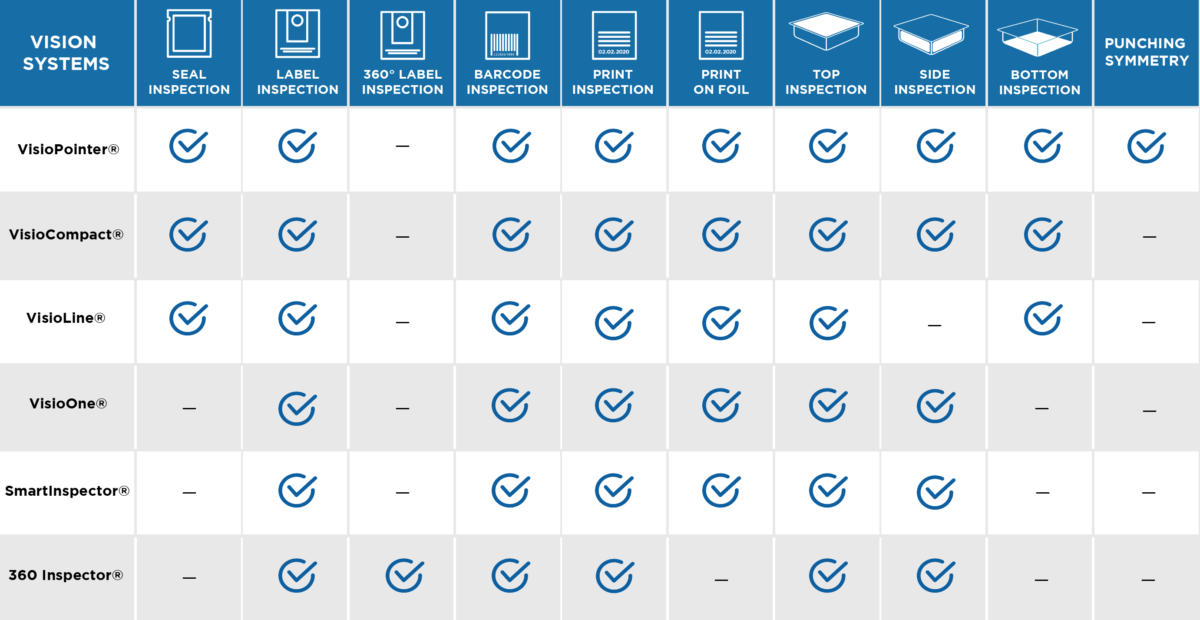

Numerous inspection types available

TriVision’s solutions offer numerous inspection types available in different configurations with seal, label and artwork, print and barcode inspection as well as top, bottom, and side cameras. Our intuitive vision software and data analytics tool enable manufacturers to optimize their production by facilitating early error detection and root cause analyses.

- Comprehensive Quality Control

Our cutting-edge equipment uses state-of-the-art vision technology to meticulously inspect and verify the accuracy of labeling, packaging, and sealing. This ensures that every product leaving your facility meets the highest standards of quality and safety. - Reduce Waste and Increase Efficiency

By detecting and correcting labeling and sealing errors early in the production process, our technology helps minimize waste and boosts operational efficiency. This not only saves costs but also enhances your brand's reputation for reliability. - Compliance with Industry Standards

Stay ahead of industry regulations and standards with our robust quality assurance system. Our technology is designed to help you meet and exceed compliance requirements, ensuring your products are safe for consumers and ready for market. - Enhanced Consumer Confidence

With flawless labeling and secure seals, consumers can trust that your products are fresh, safe, and of the highest quality. Our technology helps you build and maintain consumer confidence in your brand.

The power of TriVision technology

Discover the Power of our Label and Seal Technology

Partner with us to elevate your quality control processes. Our team of experts is ready to work with you to implement a tailored solution that fits your specific needs. Experience the peace of mind that comes with knowing your products are consistently meeting the highest standards of quality and safety.

Get in touch!

Learn more about how our label and seal technology can benefit your business. The TriVision team and our local partners are always ready to answer any questions you might have for us. Let’s discover how we can help you achieve unparalleled quality assurance in your food production operations.

trivision@trivision.dk

Call: +45 6315 4700

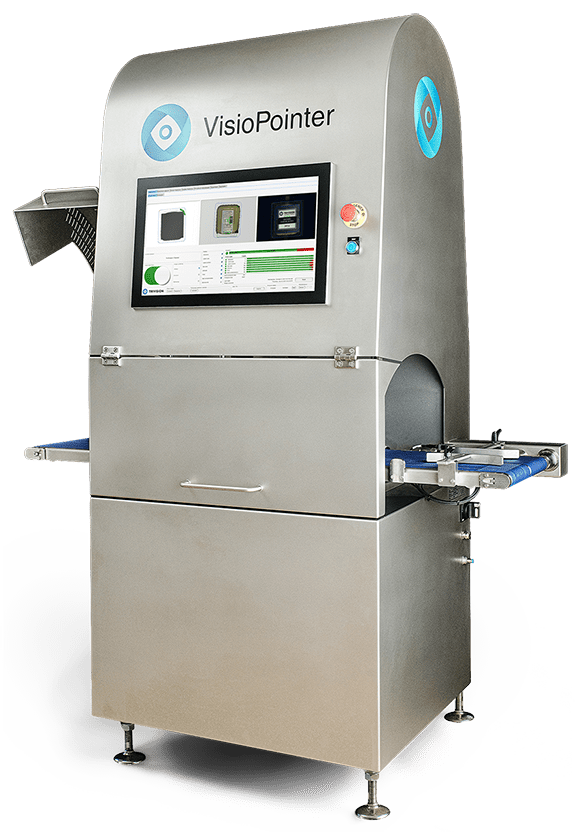

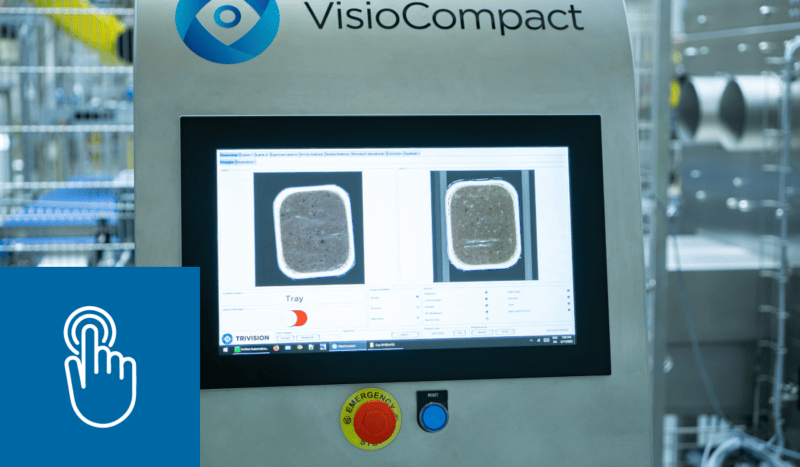

VisioPointer®

A Vision Solution for Label & Seal Inspection Combined

VisioPointer® is a high-end, state-of-the-art vision inspection system designed for thorough quality control of food packaging.

With three built-in cameras, conveyor belt, ejector mechanism and operator panel in its compact body, VisioPointer® is a turnkey solution easy to implement in most food packaging lines.

Quality Cost Reduction

REDUCE YOUR QUALITY COSTS SIGNIFICANTLY

Automate Your Way to Lower Quality Costs

TriVision's automated quality control systems release manual labour from challenging inspection tasks. Even the trained human eye faces issues when it comes to speed and accuracy in quality control, which will cause errors in the inspection process now and then.

Our vision systems consistently inspect all products at high speed, reject all faulty products without causing false rejections and reduce manual labour costs. By this the quality costs at each production line can be significantly reduced while assuring excellent quality at each food product. Our vision solutions transform quality control into a profitable investment and production optimization tool rather than just a necessary cost.

BLOG POST

How Vision Turns Quality Assurance Profitable

At TriVision, we have utilized the strengths of our leading machine vision technology to make quality assurance a profitable business case for manufacturers. The path towards turning your quality assurance into a truly profitable investment starts with understanding how TriVision systems create value for manufacturers.

MACHINE VISION-BASED

Quality Control Systems

STATE OF THE ART QUALITY MANAGEMENT SYSTEMS

TriVision Quality Control Systems

Without an automated quality control system, a number of errors on finished products that must be re-made, scrapped or returned increase significantly.

Ensure the quality of your production with 100 % quality control of food and packaging.

Competitiveness

The ability to offer customers quality products provides a strong competitive advantage.

Customer Loyalty

helps to increase client satisfaction and boost reputation by gaining customer loyalty.

Cost Reduction

Automated quality control reduces production waste and product failure costs.

“The solutions have great flexibility and are ready for future developments. This is the way forward. There is no doubt!”

- RPC SUPERFOS, DENMARK

Background

If you want to be recognized for quality and reduce the percentage of products that need to be discarded due to flaws, without spending an excessive amount of manual labor and time on label inspection and production monitoring, you need an automated quality management system.

Why Quality Control

Quality control is essential when striving to build a successful business in the manufacturing industry, delivers products, meeting or exceed customers’ expectations. It also forms the basis of an efficient business that minimizes waste and operates at high levels of productivity.

Today, production optimization represents a game changer for companies by replacing manual inspection with robot-based control for object recognition and error detection.

Competitiveness

The ability to offer customers quality products provides a strong competitive advantage. Quality helps win business from competitors who are not able to match standards and provides the opportunity to charge premium prices for a superior product.

It can also open new business opportunities in market sectors where quality is critical.

In addition quality product often equals trust from the customer.

Customer Loyalty

Quality control systems are essential in industry competitiveness as there is a high need for advanced control.

Implementing automated quality control in production helps to increase client satisfaction and boost reputation by gaining customer loyalty. Investing in a quality assurance equals investing in the future.

Cost Reduction

Quality control reduces production waste and product failure costs. With quality control systems it is possible to decrease the level of waste and rework through the production processes.

Quality control reduces production waste and product failure costs. With quality control systems it is possible to decrease the level of waste and rework through the production processes.

By reducing sunk cost due to discarded products with intelligent quality management systems, and by cutting expenditures in doing this manually, you can then benefit from the production running more efficient.

Optimize production yield efficiently

Why choose a TriVision quality management system?

Implementing a quality control system in manufacturing is essential, for the yield of production. Below we have listed the benefits of TriVisions quality control solutions.

Productivity

Low-quality outcome products lead to unnecessary expenditures for manufacturing companies.

When production is running at full capacity but doesn't deliver sellable products accordingly, the productivity is on the decline.

Profitability

Quality management systems increase profitability by helping your business to meet deadlines and minimize errors.

In addition, TriVisions quality control solutions will give you production intelligence, making it possible for manufacturers to get insight in how to reduce the expenditures linked to the discarding of flawed products, by optimizing certain processes through production.

Customer Satisfaction

Quality has a direct impact on client satisfaction. If a company consistently produces quality products, satisfied customers will turn into loyal collaborators, because their supply chain relies heavily on their supplier's ability to deliver.

Reliability and User-friendliness

TriVision quality control systems are based on decades of industry experience and more than hundred installations globally.

From the outset, the systems have been designed for practical use, and the intuitive user interface allows for easy operation without any training – also for operators.

By adopting a TriVision quality control system, you will be able to meet your customer requirements while maintaining your quality standards.

Benefits Overview

- Advanced inspection assignments can be automated with Machine Vision

- Effective label inspection improves production economy and yields

- Deep industry experience embedded makes for reliable and easy to operate solutions

CASE STORY

Scan Sverige

A new vision system provides extra security and is expected to pay for itself within the first year in production

At Scan Sverige AB in Linköping, a large variety of sausages are produced, including ”falukorv”, chorizo, kabanoss, skinless sausage, hot dogs, and even the classic ”Bullens pilsner sausage”.

Recently, a new vision system from TriVision was installed here to further ensure that the sausage is completely free from foreign particles. We talked to Johan Larsson that works as a production coordinator to discuss the new system.

As you can read from the short interview below, he was very pleased with the new system, among other reasons, because it provides extra product security and is expected to pay for itself within the first year in production.

Ensuring our raw materials are free from plastic

Ideally, we don't want to find anything, but when we do, it’s a real reassurance that the machine does its job and ensures our raw materials are free from plastic.

Johan Larsson

Production Coordinator, Scan Sverige AB, Linköping

What was the reason for investing in the vision system?

- In the food industry, we are always looking for new ways to secure every part of the production, all the time. It's so easy during cutting or from external suppliers, for a plastic bag or something else that shouldn't be there to get into our system with the meat, and that contaminates a lot of raw materials.

Is the reduction of waste the most important benefit of the system?

- Yes, you could say that since the loss of raw materials is also associated with very high costs. When TriVision’s system can find pieces of plastic that are 5 x 5 mm and larger, we can save a lot of raw materials from being simply thrown away.

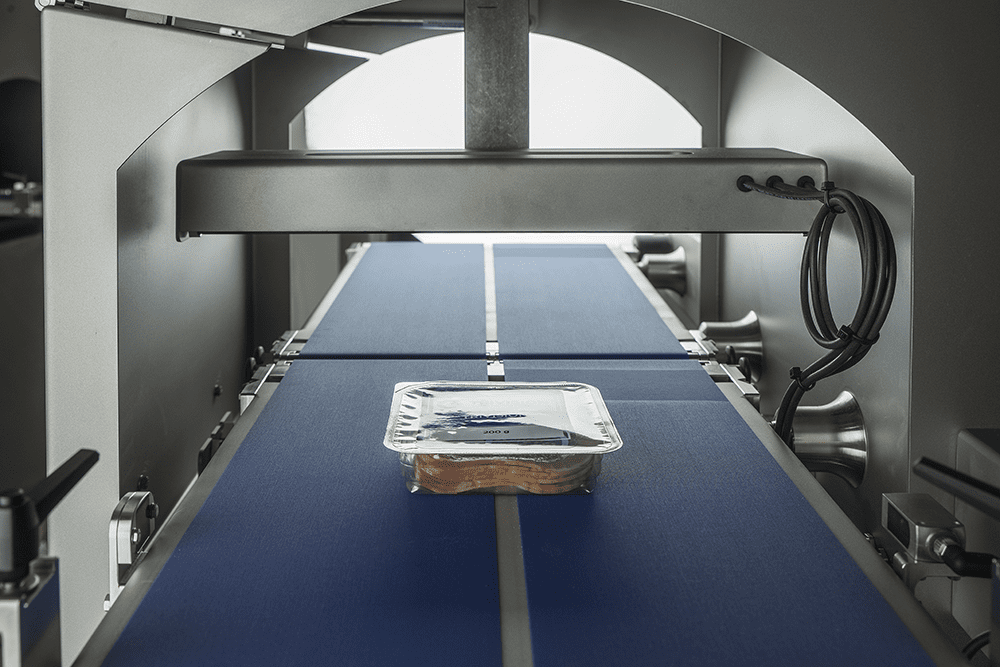

More about the vision system

The vision system consists of an advanced camera placed about two meters from the conveyor after the actual grinder. Lights illuminate the area that the camera scans. When the system detects an anomaly, both the belt and grinder stop, and an alarm on the screen informs about what has been detected.

- It's an easy-to-operate system once it's installed, just press a button and let the system do its job, says Johan Larsson

Was it a good investment to purchase and install the system?

- Yes, it was a good investment. We estimate that it has paid for itself after the first year in operation, which must be considered a good investment. It fulfills the purpose of securing our products. It hasn't been running for long, and it has only stopped the system once, but just that incident has already saved a lot. Costs during downtime always depend on how much raw material we must throw away, says Johan Larsson, concluding:

- Ideally, we don't want to find anything, but when we do, it’s a real reassurance that the machine does its job and ensures our raw materials are free from plastic.

What Makes TriVision Special?

We are Machine Vision Pioneers

- Specialized in Inspection Solutions for the Food and Pharma Industries

Founded by pioneers in machine vision, TriVision has been automating inspection processes for over 20 years. Our vast experience and expertise in both machine vision technology and the unique conditions of food and pharma production environments have built the deep knowledge and capabilities we have today.

At TriVision, we understand the power and the pitfalls of machine vision, an advanced technology we have perfected over time to make it intuitive, reliable, and efficient. This ensures it’s not only accessible but also a strong business asset for the food and pharma industries.

With a pioneering mindset, TriVision continues to push the limits of this technology, maximizing its application and impact. We help producers ensure compliance, enhance product safety, improve efficiency, reduce waste, and support sustainability in the food and pharma industries.

Our mission

To support the food and pharma industries in optimizing and delivering safe, high-quality products while minimizing waste and environmental impact

Our vision

To become the food and pharma industries' preferred supplier of vision inspection solutions

Trivision systems

We Make Vision Systems

with Real Impact

TriVision Systems operate in plants worldwide, maximizing production performance and providing a great business case in multiple ways.

Our solutions are designed to make a real impact on productions by ensuring product safety and compliance, while reducing QC costs, failure costs, waste, and downtime, and by facilitating production optimization.

Powered by our leading, proven machine vision technology, our systems achieve significant results. Each solution embodies the unique features and advantages of our technology and approach, which we have perfected over the years to make it both accessible and highly effective for the food and pharma industries.

Here's How We Do it

Reliable Inspection

TriVision’s proven vision technology provides a reliable inspection and failure detection that producers can count on.

We have vast experience within the field and know the pitfalls, and our technology has been developed to handle various natural variations in produced products.

Producers can rely on our systems to ensure that only approved products comply and that defective products are rejected.

Intuitive Operation

You might need a PhD to develop our systems, but you don't need one to use them. TriVision systems are made intuitive and user-friendly for operators.

For producers to utilize all features and functionalities daily to ensure compliance and efficient production, it is crucial that the HMI is simple and logically built according to an operator’s priorities.

With just a few clicks, operators can e.g., get an overview of production performance, adjust tolerances for quality levels, make changeovers or investigate the errors in defective products.

Intelligent Data Utilization

TriVision systems generate quality data from every inspected product, and we provide efficient cloud-based tools that crunch and deliver valuable insights.

With elaborate production statistics, producers can make informed decisions when planning their next optimization initiative.

The data helps uncover trends across production lines, products, shifts, raw materials, and various process parameters.

Turnkey Solutions

TriVision develops plug-and-play solutions that offer producers the advantages of machine vision inspection while eliminating its complexity.

Our systems are designed as turnkey solutions, complete with all necessary mechanics, vision components, and software.

They are engineered to save valuable footprints and meet the specific requirements of the food and pharma industries.

Who are we?

Short Summary

- TriVision was founded by machine vision pioneers in 2000

- We specialize in machine vision technology for the food industry and pharma industry

- Our user-friendly systems inspect both packaging and products in plants worldwide

- TriVision is one of the only companies in the world offering turnkey solutions that both inspect seal and label on packaging

- Our vision inspection systems ensure quality assurance, compliance, product safety, reduced costs and waste, as well as OEE optimization

News

TriVision Enters The Finnish Market With Haarla OY

TriVision and Haarla OY join forces to bring TriVision’s standardized vision inspection solutions into Finnish food manufacturing facilities. The collaboration holds a great potential for success as Finnish food manufacturers, due to tough market conditions and challenges, significantly and in many ways can benefit from applying TriVision’s automated inspection.

With Haarla OY as new partner and distributor in the Finnish market, TriVision expands its distributor network to 15 partners worldwide.

Finland is a market of great opportunity for the new constellation as Finnish food manufacturers face tough market conditions such as Finnish production salaries as well as Finnish retailer prices being among the highest in Europe. Hence, TriVision’s solutions cannot only help Finnish manufacturers across food sectors to ensure product quality and food safety, but also significantly reduce quality assurance costs, expensive food loss and waste through reliable automated inspection and intelligent data utilization.

By joining forces with Haarla OY, TriVision will have a local Partner that effectively can promote these benefits to the Finnish manufacturers and provide efficient implementation of TriVision’s solutions:

“We see Haarla OY as an attractive partner for multiple reasons. Besides having run a solid business for years as a supplier for the food manufacturing industry, the Haarla team also possesses great technical abilities, great knowledge about machine vision and a professional approach to their market and customers”, says Jesper Bach, Managing Director at TriVision.

Haarla OY is a family-owned business founded back in 1962 and has been supplying e.g. quality measurement instruments to the food manufacturing industry for years. With the Company’s competences and strong position within the food industry combined, large Finnish food manufacturers can expect an introduction to TriVision’s solutions anytime soon:

“Having existed for many years, Haarla has created strong customer relationships and is perceived as a strong, trustworthy advisor. I think it won’t be long before we will be preparing our first system with a Finnish interface”, says Jesper Bach.

Haarla will be distributing a range of TriVision’s standardized machine vision systems for automated quality control of food packaging. Hence, Finnish manufacturers can look forward to not only getting their hands on accurate label and date marking verification, but also the world’s most reliable visual verification of package seals, based on TriVision’s leading vision technology.

Insights

An Introduction to Machine Vision

What is Machine Vision Inspection?

Machine Vision Inspection is a technology based on image processing that is used to automate inspection processes in production lines in various manufacturing industries. Basically, it allows a computer to inspect and evaluate product quality using industrial cameras, lights, and computer vision software.

The technology is used to perform high-speed, reliable quality control to ensure product quality and improve overall efficiency as it releases manual labour from repetitive and challenging inspection tasks and/or expands the existing quality control.

Additionally, by digitising the inspection process and generating documenting data, machine vision inspection can be used to provide production data and statistics, which can facilitate production optimisation.

Due to its wide application and efficiency, machine vision inspection is widely and increasingly used in several manufacturing industries such as automotive, electronics, food and beverage, pharmaceuticals, packaging, labelling, and printing.

Machine vision-based inspection is carried out by a machine vision system.

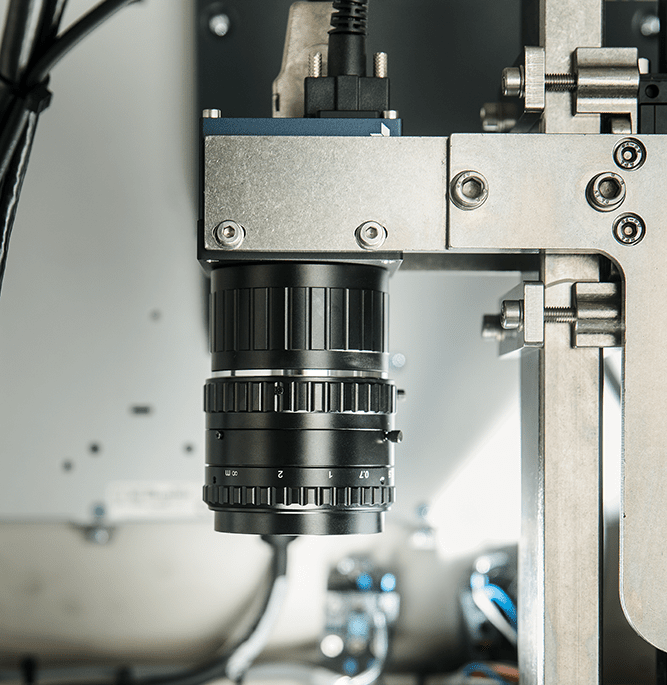

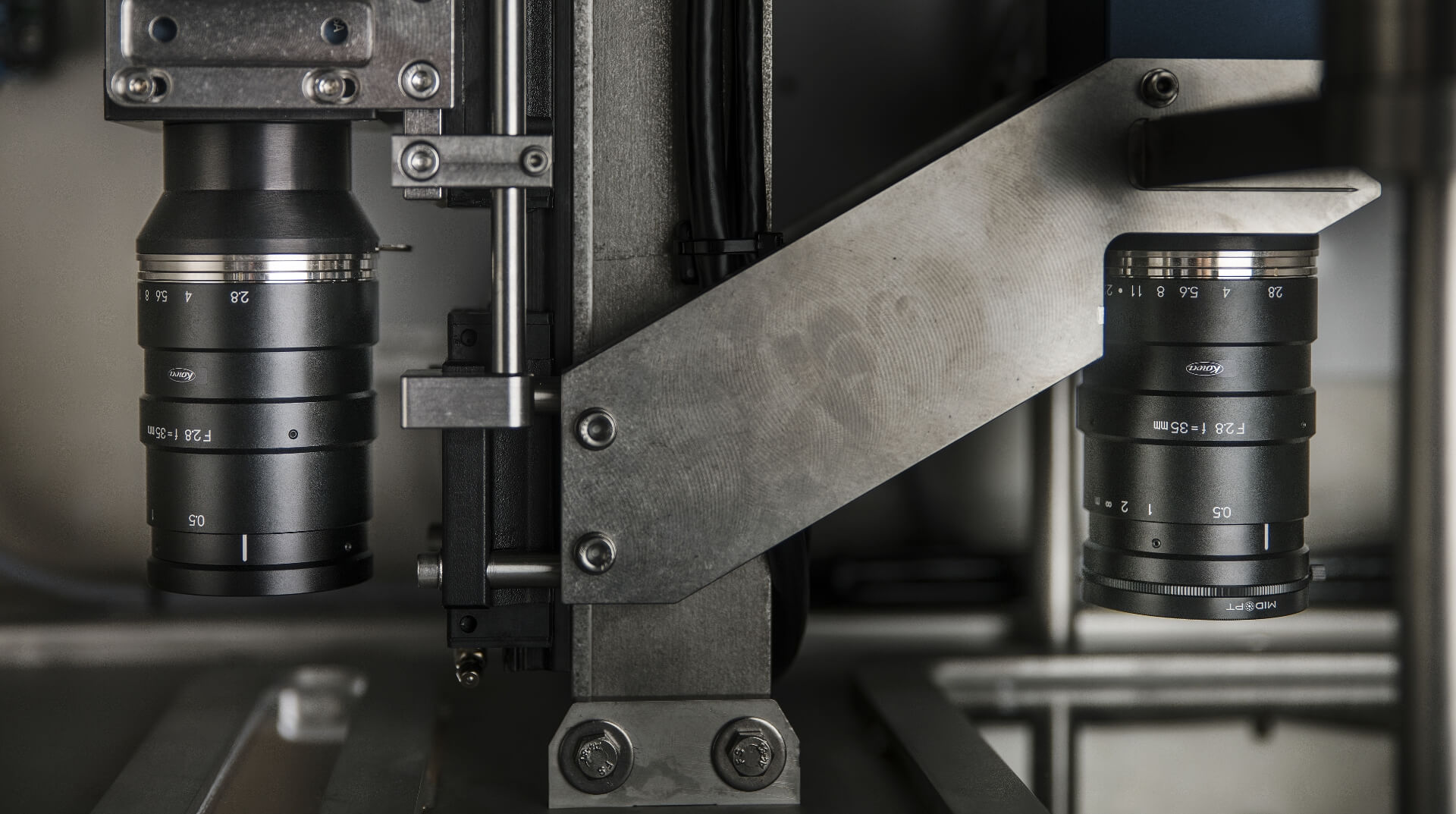

What does a Machine Vision System consist of?

A Machine Vision Inspection System consists of hardware components, the system’s body, and computer vision software, which can be considered as the system’s brain.

The Hardware Components

A Machine Vision system’s exact hardware setup depends on its specific inspection tasks and hence configuration, but basic components of a Machine Vision System count:

- Sensors that identify the presence of incoming objects

- Cameras, the eyes of the system, used for acquiring images of the

objects that are to be inspected. - Lights and often a housing to ensure optimal light for the image acquisition.

- A PLC for controlling the system logic i.e., inputs, outputs and other actions from hardware components.

- An industrial computer running the computer vision software that analyses the acquired images and provides a HMI.

- An operator panel that visualises data and enables operators to control the system.

The Computer Vision Software

The brain of the Machine Vision System, the computer vision software, should be perceived as a library containing several software packages that each provides a specific inspection type, i.e., enables the system to inspect and evaluate specific elements of an object.

It processes and evaluates the acquired image of the inspected object to answer the important question: Does the inspected object have any defects compared to the desired quality level set by the producer?

How does Machine Vision Inspection work?

When a machine vision system inspects an object, the following steps take place:

- Image Acquisition

First, when the incoming object approaches the system, it is detected by a sensor. Light sources and cameras act on the sensor’s input by lighting up the area and capturing an image of the object at exactly the right time.

Nothing happens without a successful image acquisition. Using the right optics and lighting technique is key to ensure high image quality, which is fundamental for carrying out an accurate, reliable analysis and hence quality control.

- Image Processing and Analysis

The acquired image is pre-processed by applying algorithms and a number of specific filters – to detect the product in the image and highlight the key features of interest. Based, on the filtered image, algorithms are then used to generate a data object – data containing the characteristics of inspected object’s highlighted features.

The design of an algorithm impacts the efficiency of the image processing and analysis. Powerful algorithms facilitate accurate, high-speed vision inspection, and hence maximises product quality and throughput.

- Result evaluation

The system’s software compares the extracted data object, i.e. the characteristics of the object’s highlighted key features with a set of predefined tolerances, which defines a producer’s target quality level.

- Decision Making

Finally, based on the comparison between the processing results and the set tolerances, decisions are made by the system. The inspected object will get a classification e.g. passed or failed. Some machine vision systems will be able to reject the product or initiate warnings, alarms, etc.

- Process Control

Some machine vision systems additionally utilise the gathered inspection data to spot trends in the production, and give recommendations to the machine operators for production optimisation. This can be done via data platforms that provide production data overviews highlighting crucial production information.

An overview of production data can help manufacturers to understand why faulty products and errors occur and support them in identifying root causes. Also the adjustment of process parameters can be monitored and evaluated to optimise the overall production, and the performance of different shifts, production lines and production facilities can be compared to align and optimise production procedures.

Machine Vision Inspection in the Food Industry

Machine Vision inspection is an attractive technology for food producers to meet the high demands and cope with the challenges they face.

Not only are customers and retailers increasingly demanding high product quality and quality documentation – food producers simultaneously need to optimise to remain profitable, focus on sustainability and deal with labour shortages.

What can Machine Vision Systems check?

The application of machine vision inspection is vast, which means that any food producer in any sector can utilise the power of the technology to handle specific issues related to product quality.

Machine vision systems can be implemented into different production lines and configured to match specific application and inspection requirements.

Food producers can utilise machine vision inspection to perform:

- Inspection of food and packaging appearance

- Presence/absence check

- Orientation check

- Verification of amount and shape

- Colour inspection

- Foreign object detection

- Seal inspection and validation

- Label check and verification

- Reading and check of printed date markings

- Reading and check of barcodes and QR codes.

Machine Vision Systems are The Eyes of The Robots

As automation is key to increase efficiency and deal with labour shortages, producers are focusing on automating older existing production lines. Robots are replacing people in processing and packaging lines to increase throughput. And new production facilities are built fully automated today.

Hence, dark factories are the future, meaning that factories in theory would require no lights, as all processes are fully automated by machines.

It also means that new quality control solutions are required as producers do not have the same number of people on the production floor to monitor product quality, and increased production speeds due to an increasing automation level leave workers with inspection tasks that challenge the human eye.

This makes machine vision inspection a technology of the future. With its ability to inspect all produced products and detect the tiniest deviations and errors consistently and reliably over time at high speeds, enabling producers to meet the high demands of consumers and retailers while increasing efficiency.

More Machine Vision Insights

How to utilise the Machine Vision Technology

Even though machine vision holds great potential for boosting quality and production performance, it is a technology that is difficult to master and utilise consistently for efficient quality control. But if utilised properly, machine vision can boost a producer’s quality and production performance.

Read about how to achieve efficient quality control by using machine vision here

Discover all the benefits of Machine Vision Inspection

If utilised properly, food producers can implement machine vision systems in both food processing and packaging lines to improve product quality and documentation while reducing costs and facilitating optimisation of production processes.

Discover how Vision inspection in many ways can improve food producers’ business performance here.

Label Inspection

HIGH-SPEED IN-LINE LABEL INSPECTION

Efficient Label Inspection

and Label Verification

Proper labeling of all packages leaving the factory is crucial to ensure product safety and compliance with regulations. It is important that consumers can identify package content, with allergens highlighted clearly to prevent allergic reactions.

Labeling errors can occur due to incorrect, damaged, or inaccurately positioned label or foil rolls, often caused by equipment malfunctions or incorrect settings.

TriVision solutions can inspect and verify food and pharma labels inline immediately after the labeling and printing process, ensuring quality control and assurance.

Solutions for Label Inspection

VisioPointer®

for the most thorough inspection

VisioCompact®

stand-alone solution

SmartInspector®

within a minimal footprint

VisioLine®

for integration into thermoformers

VisioOne®

for essential packaging applications

360 Inspector®

designed to inspect round bottles, cans, and jars

Detect Incorrect

and Missing Labeling

Sometimes, incorrect label rolls are applied, or packages are missing labels altogether. If products with incorrect labeling make it out of the factory, it can be very costly for producers.

TriVision solutions provide an efficient way for producers to validate food labels, helping to prevent expensive recalls and meet retailer demands.

Prevent and Detect

Offset and Rotated Labels

Even when the correct label is applied, errors such as misaligned or rotated labels can still occur. These errors may occur if the label machine is not properly adjusted or if there are problems with the product infeed.

TriVision’s vision-based label inspection uses images and qualitative data to detect errors and trends. Operators receive alerts, enabling them to make swift adjustments, minimizing the occurrence of errors and even preventing them altogether.

INLINE PRINT INSPECTION

Inspection and Reading

of Printed Markings

Labels in the food and pharma industries include information such as expiration dates, packing dates, weight, and price, which are printed in-line.

TriVision solutions inspect and verify these labels, ensuring that printed details are accurate, correctly positioned, and readable.

Discover how TriVision solutions also verify printed marking without causing the common issue of false ejections.

ERP & MES INTEGRATION

Verify Valid Label Data

from ERP & MES Systems

TriVision systems are made for smart manufacturing and can be integrated with ERP and MES systems.

This allows producers to automatically push valid label data directly from ERP and MES systems to the vision systems and utilize it during the label verification.

LABELING DOCUMENTATION

Be a Trustworthy Supplier

With Complete Documentation

Every inspection collect images and quality data, providing comprehensive documentation of the labeling and verification process for all shipped products.

This level of documentation strengthens manufacturers’ position towards retailers, as they can offer added value by guaranteeing regulatory compliance.

case story: St. Clemens

A faster, safer, and more efficient production line

As the cheese industry is increasingly implementing vision technology and automation, St. Clemens wanted to invest in a more efficient and automated packaging line. Consequently, they chose to implement TriVision’s VisioPointer® to streamline the inspection process for their triangled danablu cheese. When asked why they chose TriVision, St. Clemens cited several crucial factors...

PACKAGING INSPECTION SOLUTIONS

A Range of

Plug-and-Play Solutions

TriVision’s standardized Plug-and-Play solutions for packaging inspection are all built upon the same leading technology and software.

TriVision's various vision systems offer tailored solutions to meet the specific needs of different types of packaging lines and inspection requirements.