Cheese

Cheese Industry

Get Every Cheese

Product Right

Producing the perfect cheese is an art. It is all about creating the same taste, texture and appearance in every cheese, which is difficult as the production process is long and complex.

Cheese producers know that small adjustments matter. And consumers want the cheese experience they value every time. Our vision inspection solutions help producers achieving consistency in product quality and delivering the perfect cheese experience in every product.

Inspection of Cheese Packaging

Solve Typical

Cheese Packaging Issues

Various errors may occur when cheese products such as cheese slices are packed. Cheese might get stuck in the seal, which causes a bad appearance, possibly leakages and hence a reduced shelf life. Or the cheese product can be labelled incorrectly.

TriVision offers a number of solutions that automate the inspection of cheese packaging to ensure its quality efficiently.

Colour Inspection

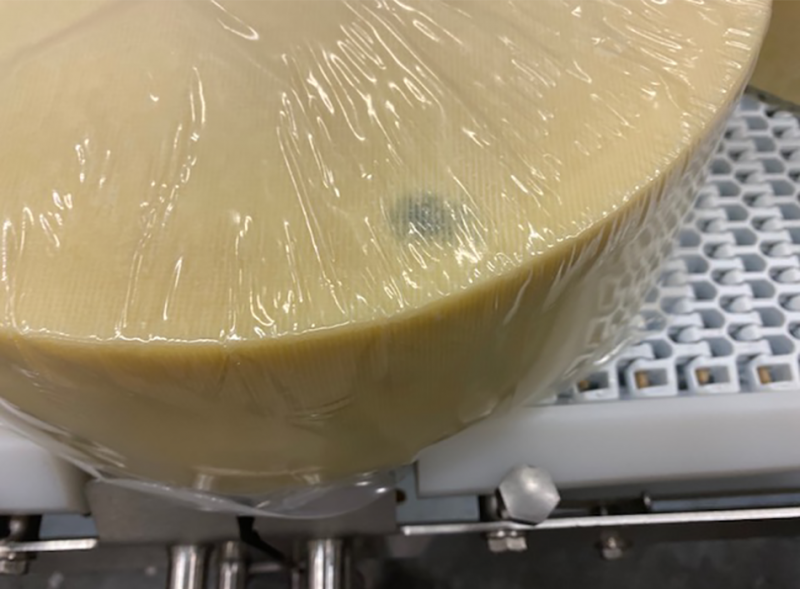

Mold Detection

A common challenge in cheese productions is when mold spots occur in cheese blocks during the ripening, when e.g. oxygen is present below the plastic, if moisture occurs or if the temperature is too high, causing bacteria to grow during the cheese's maturing time.

We inspect cheese blocks before the debagging process to help cheese producers avoid large costs related to mold spores being spread the production facility, typically causing significant downtime as extensive cleaning is required. And of couse, recalls and sales declines related to mold issues are also avoided.

Foreign Object Detection

Detection of Plastic

After the debagging cheese blocks, it is important for cheese producers to ensure that no plastic pieces are stuck in the surface. Many producers use manual inspection, which requires manual labour performing tidious work and involves the risk of human errors.

TriVision has developed an efficient turnkey solution that automates the inspection of cheese blocks after debagging.

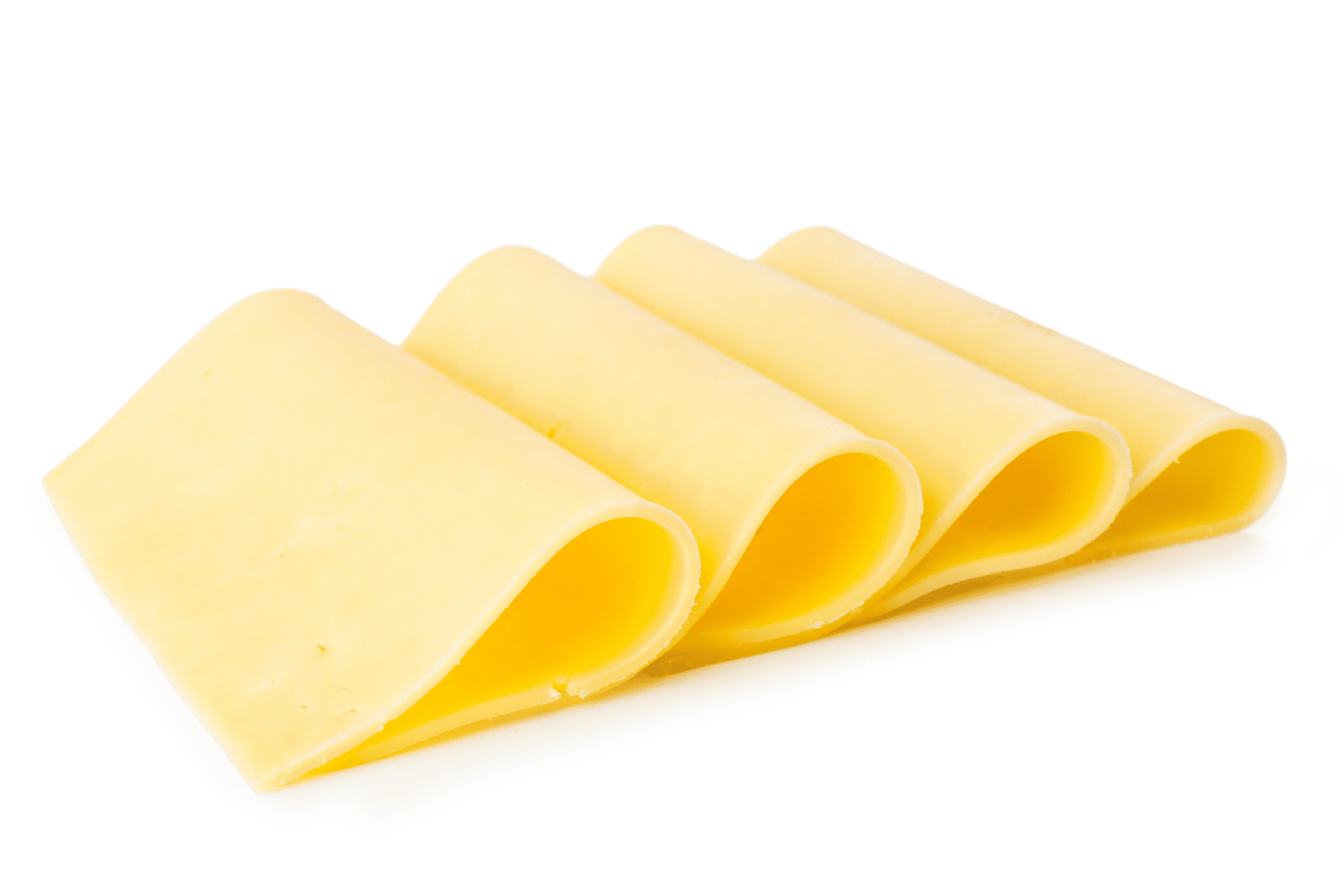

Slice Inspection

Checking Cheese Slices

TriVision also offers solutions for checking cheese slices before stacking, checking each slice's size, shape, colour and position on the conveyor - to ensure that all slices are complete, have a uniform look and can be properly stacked.