Label Inspection

HIGH-SPEED IN-LINE LABEL INSPECTION

Efficient Label Inspection

and Label Verification

Proper labeling of all packages leaving the factory is crucial to ensure product safety and compliance with regulations. It is important that consumers can identify package content, with allergens highlighted clearly to prevent allergic reactions.

Labeling errors can occur due to incorrect, damaged, or inaccurately positioned label or foil rolls, often caused by equipment malfunctions or incorrect settings.

TriVision solutions can inspect and verify food and pharma labels inline immediately after the labeling and printing process, ensuring quality control and assurance.

Solutions for Label Inspection

VisioPointer®

for the most thorough inspection

VisioCompact®

stand-alone solution

SmartInspector®

within a minimal footprint

VisioLine®

for integration into thermoformers

VisioOne®

for essential packaging applications

360 Inspector®

designed to inspect round bottles, cans, and jars

Detect Incorrect

and Missing Labeling

Sometimes, incorrect label rolls are applied, or packages are missing labels altogether. If products with incorrect labeling make it out of the factory, it can be very costly for producers.

TriVision solutions provide an efficient way for producers to validate food labels, helping to prevent expensive recalls and meet retailer demands.

Prevent and Detect

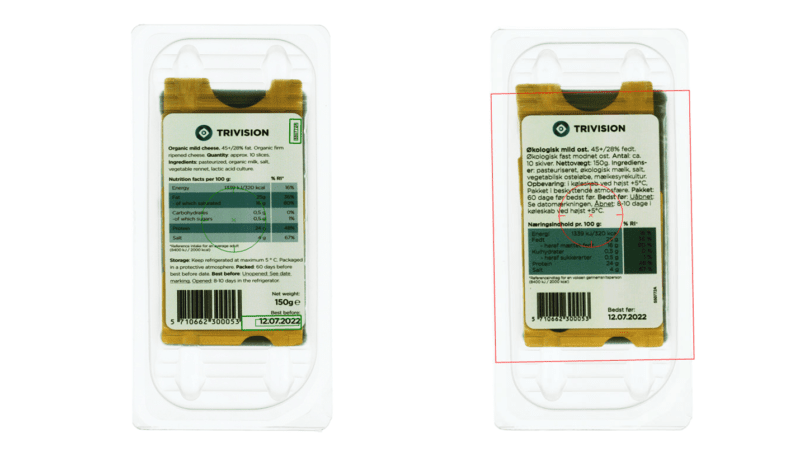

Offset and Rotated Labels

Even when the correct label is applied, errors such as misaligned or rotated labels can still occur. These errors may occur if the label machine is not properly adjusted or if there are problems with the product infeed.

TriVision’s vision-based label inspection uses images and qualitative data to detect errors and trends. Operators receive alerts, enabling them to make swift adjustments, minimizing the occurrence of errors and even preventing them altogether.

INLINE PRINT INSPECTION

Inspection and Reading

of Printed Markings

Labels in the food and pharma industries include information such as expiration dates, packing dates, weight, and price, which are printed in-line.

TriVision solutions inspect and verify these labels, ensuring that printed details are accurate, correctly positioned, and readable.

Discover how TriVision solutions also verify printed marking without causing the common issue of false ejections.

ERP & MES INTEGRATION

Verify Valid Label Data

from ERP & MES Systems

TriVision systems are made for smart manufacturing and can be integrated with ERP and MES systems.

This allows producers to automatically push valid label data directly from ERP and MES systems to the vision systems and utilize it during the label verification.

LABELING DOCUMENTATION

Be a Trustworthy Supplier

With Complete Documentation

Every inspection collect images and quality data, providing comprehensive documentation of the labeling and verification process for all shipped products.

This level of documentation strengthens manufacturers’ position towards retailers, as they can offer added value by guaranteeing regulatory compliance.

case story: St. Clemens

A faster, safer, and more efficient production line

As the cheese industry is increasingly implementing vision technology and automation, St. Clemens wanted to invest in a more efficient and automated packaging line. Consequently, they chose to implement TriVision’s VisioPointer® to streamline the inspection process for their triangled danablu cheese. When asked why they chose TriVision, St. Clemens cited several crucial factors...

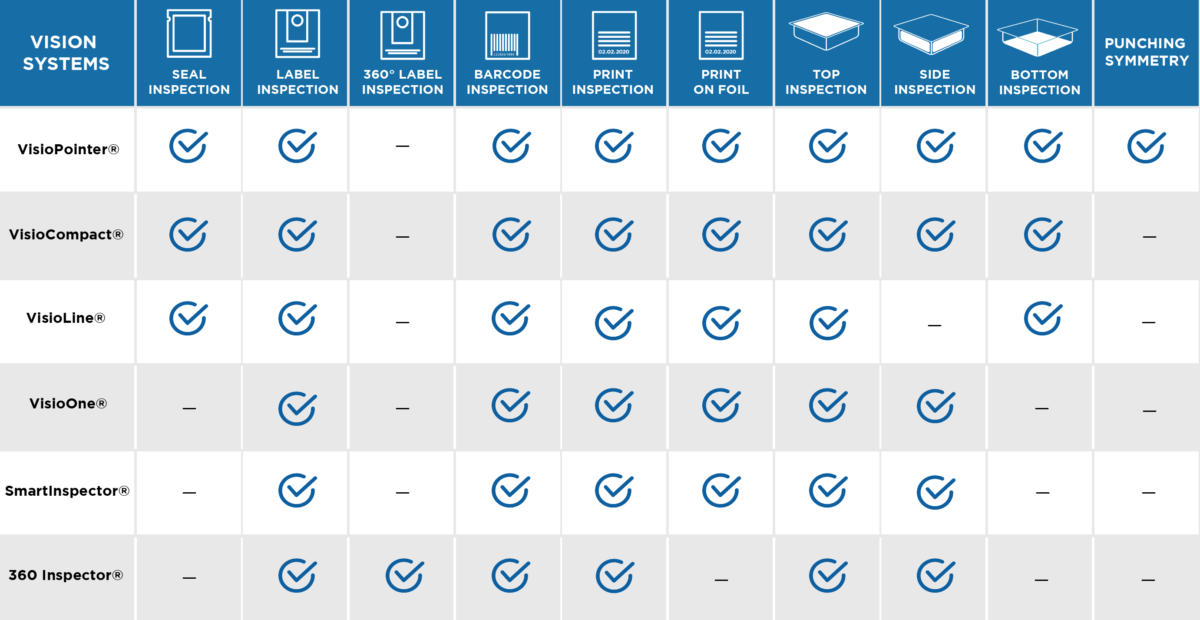

PACKAGING INSPECTION SOLUTIONS

A Range of

Plug-and-Play Solutions

TriVision’s standardized Plug-and-Play solutions for packaging inspection are all built upon the same leading technology and software.

TriVision's various vision systems offer tailored solutions to meet the specific needs of different types of packaging lines and inspection requirements.