Great news for food manufacturers!

TriVision introduces

360 Inspector and VisioOne

TriVision is proud to introduce a pair of highly effective vision solutions to ensure that your labels, prints, and barcodes are of top-notch quality.

Quick overview:

- 360 Inspector® is an essential turnkey solution for inspecting products requiring vision from all angles such as round bottles, cans, and jars.

- VisioOne® is a flexible vision inspection solution installed on top of an existing conveyor, ensuring a swift and simple changeover.

Two Very Different but Equally Effective Vision Inspection Solutions

360 Inspector

Vision Inspection with cameras covering 360-degrees

A comprehensive vision inspection system designed to inspect round bottles, cans, and jars. By reliably identifying and ejecting products with critical defects or irregularities in label and/or print, 360 Inspector® reduces downtime and increases efficiency.

The system is available with or without a conveyor. It inspects label and artwork, print, and barcode.

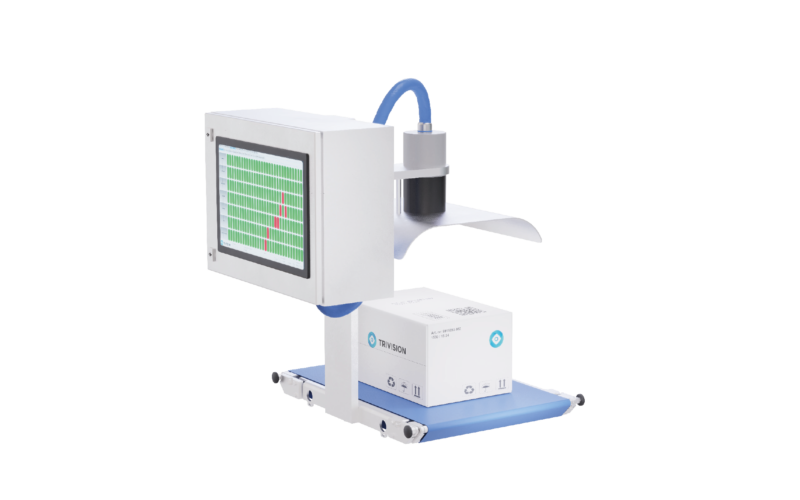

VisioOne

A Flexible Vision Solution

This is your flexible vision solution for all essential packaging inspection. VisioOne is installed on top of an existing conveyor ensuring a swift and simple changeover.

With a single camera, VisioOne® efficiently verifies labels of primary and secondary packaging. The system provides an effective real-time overview of inspection data and production performance as well as documentation of compliance & elaborating production statistics.

More News from TriVision