CASE STORY

St. Clemens

A faster, safer, and more efficient production line

St. Clemens, located on the Danish island Bornholm, is a leading manufacturer in the Scandinavian dairy industry and exports to extensive regions worldwide. They specialize in producing milk, ice cream, and cheese, including the renowned Danablu cheese.

As the cheese industry is increasingly implementing vision technology and automation, St. Clemens wanted to invest in a more efficient and automated packaging line. Consequently, they chose to implement TriVision’s VisioPointer® to streamline the inspection process for their triangled danablu cheese.

The VisioPointer® offers a comprehensive solution, ensuring faster, safer, and more efficient inspections compared to manual methods. By integrating the VisioPointer® into their product line, St. Clemens ensures delivering flawless products.

When asked why they chose TriVision, St. Clemens cited several crucial factors, including TriVision's expertise, experience, and competitive pricing. Please watch the short video at the bottom of the page to get the complete story.

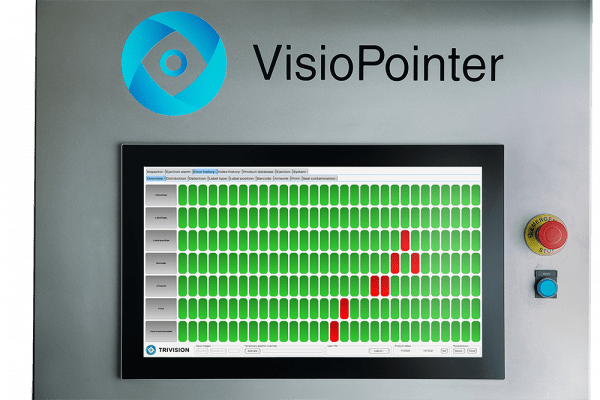

VisioPointer® is highly intuitive

“The interface is easy to use, and once you get to know the system, it is extremely simple to add new products in the system, define label position, appearance etc.”

René H. Olsson

Packaging Manager at St. Clemens

VisioPointer®

A Turnkey Vision Solution for Thorough Packaging Inspection

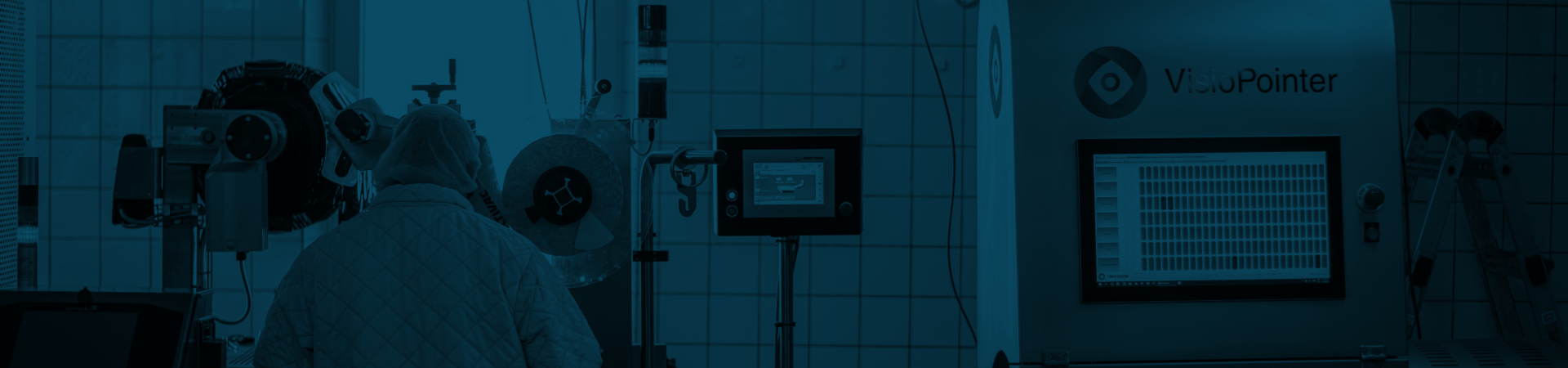

VisioPointer® is a high-end, state-of-the-art vision inspection system designed for thorough quality control of food packaging.

With three built-in cameras, conveyor belt, ejector mechanism and operator panel in its compact body, VisioPointer® is a turnkey solution easy to implement in most food packaging lines.

VisioPointer® Boosts Quality and Efficiency

What do the customers say about VisioPointer®?