News

New TriVision range automates quality control of cheese blocks

TriVision is offering a groundbreaking automated solution for all producers handling and unwrapping cheese blocks during their production.

The CheeseInspector® range is the first real automated solution providing an efficient alternative to manual inspection of cheese blocks. The range of vision systems enables producers to ensure compliance while reducing costs significantly:

“Our CheeseInspector® range answers questions that producers handling cheese blocks have been asking increasingly since automation and industry 4.0 became a hot topic: how can we ensure compliance efficiently? It is not efficient to use two or even three workers at each production line to manually inspect all produced blocks. But it has been necessary, as no better alternatives have been available. We saw this need and gap in the market and address it today by offering a range of vision systems specifically designed for cheese block inspection. All powered by our well-known industry-proven vision technology”, says Jesper Bach, CEO at TriVision A/S.

Producers handling cheese blocks typically rely heavily on manual labour inspection to perform business-critical inspections. When applying the foil ripening method, it is crucial to check each block for mold spots and plastic pieces on the surface - before and after the foil removal process, respectively.

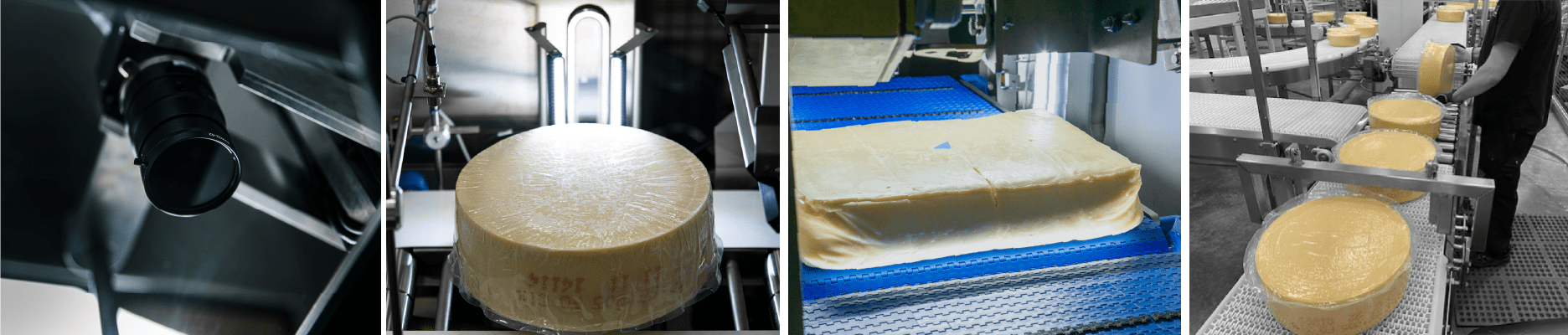

CheeseInspector® solutions automatically inspect the entire surface of both rectangular and round cheese blocks.

The range consists of multiple standardized, stand-alone vision systems for cheese block inspection covering different applications. The range´s versatility enables handling both rectangular and round cheese blocks of different formats and sizes.

The machine shown to the right is the CheeseInspector® Rectangular, an automated vision quality control system for rectangle cheese blocks.

A great business case with fast ROI

TriVision’s CheeseInspector® has been an attractive business case for several producers as it addresses several challenges and brings several benefits. It first and foremost ensures reliable quality control and compliance, by releasing workers from challenging inspection tasks, preventing human errors during the inspection process that can result in significant failure costs.

Additionally, producers can achieve a fast ROI by automating the inspection process and reducing QC costs as significant manual labour resources typically are used for the inspection.

“Our great traction with the cheese inspection solutions confirms that we are addressing real challenges in an efficient way, presenting decision makers with an attractive ROI.”

Jesper Bach

CEO at TriVision A/S

TriVision CheeseInspector® being a great business case also shows in the vast interest for the range. Several large producers have already ordered systems from the range since being launched in 2022:

“We are experiencing a lot of interest and have achieved great sales results within our CheeseInspector® range already – not only in Europe, but also in the US. So, we expect this part of our business to grow significantly in the coming years. Our great traction with our cheese inspection solutions confirms that we are addressing real challenges in an efficient way, presenting decision makers with an attractive ROI” says Jesper Bach, CEO at TriVision A/S.