CHEESE SURFACE INSPECTION

Reliable Detection of

Mold and Foil Residues

TriVision offers a range of turnkey vision systems for automating business critical quality control of cheese blocks, ensuring compliance, avoid failure costs and protect business.

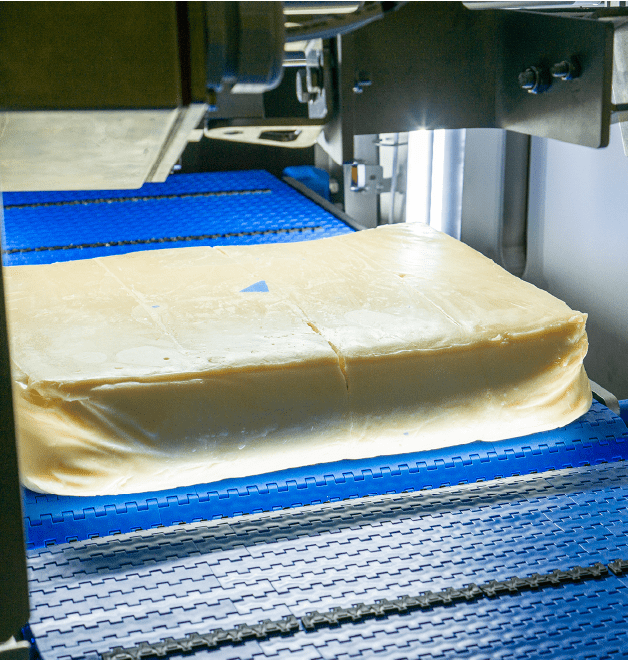

The solutions are implemented inline to check every cheese block after the foil ripening process. Mold spots might occur in processed cheese blocks, and plastic might get stuck on the surface after the foil removal process.

Hence, CheeseInspector® can be implemented before and after de-baggers for respectively mold and plastic detection of round and rectangular cheese blocks.

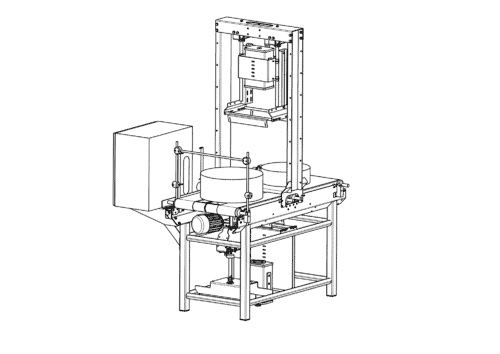

THE CHEESEINSPECTOR® RANGE

The Most Efficient

Cheese Inspection Solutions

With decades of experience within the cheese industry and in developing efficient inspection systems, TriVision has developed a leading range of solutions for cheese block inspection.

TriVision's CheeseInspector® range is characterized by key traits making it a great business case:

- Reliable detection of mold and plastic

- High efficiency - *up to 15 blocks per min

- Easy to operate.

- Compact systems with minimum footprint

- Fast ROI.

Eliminate QC and failure costs

Automate and Achieve

a Fast Return on Investment

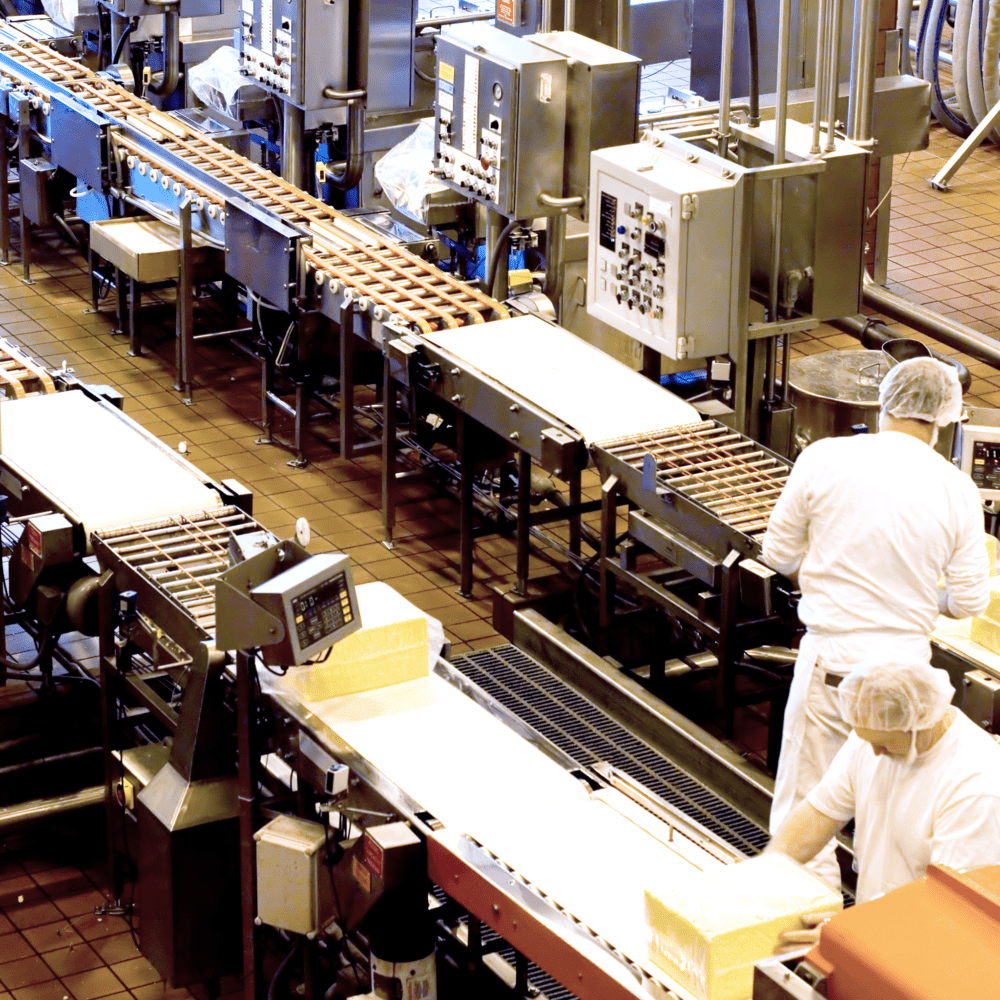

Producers handling cheese blocks typically rely on significant manual labour resources for manual inspection. Just by considering the automation and reduction of manual labour costs, TriVision's CheeseInspector® becomes an attractive business case. The compact vision systems require limited investment and releases significant manual labour resources, providing a fast return on investment.

Producers can automate and optimize without compromising on product quality, by relying on TriVision's reliable, industry-proven failure detection.

The ensured compliance will only make the business case even better, by preventing expensive production stops and recall costs.

Introducing CheeseInspector®

Application Examples

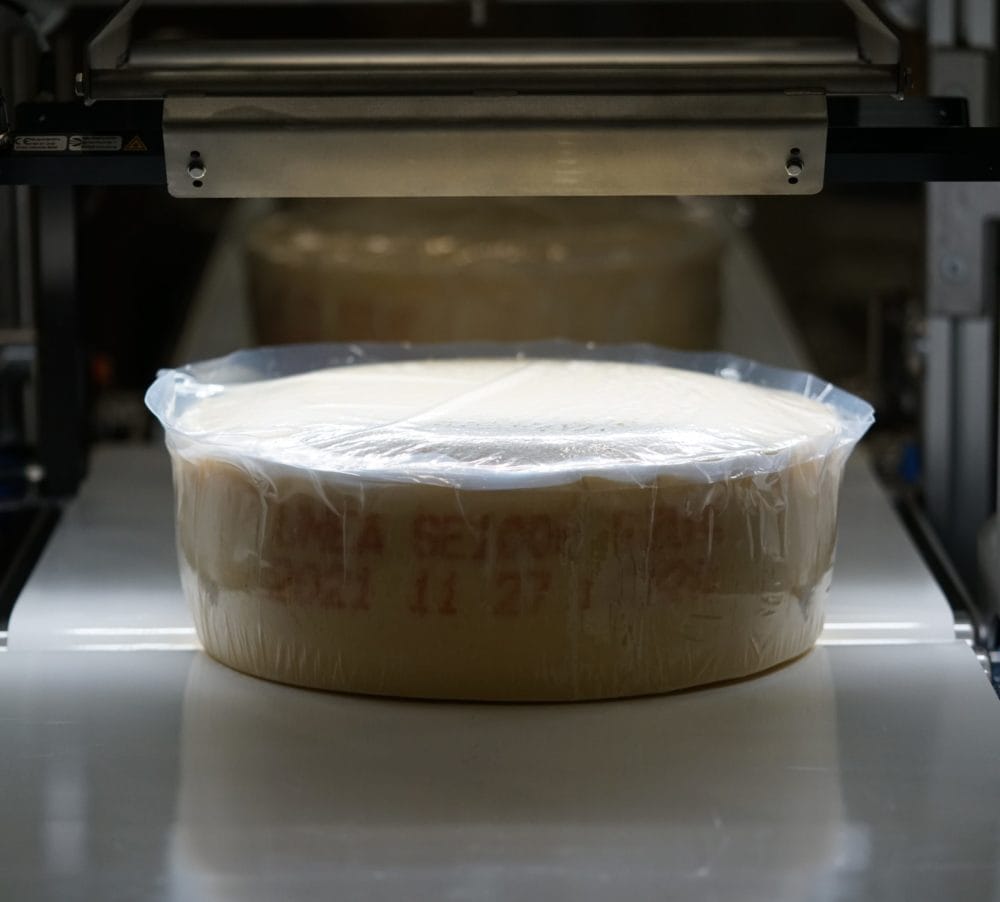

Foil Detection

after de-bagging, checking for foil residues.

Mold Detection

Inspection of a round cheese block

before unwrapping, checking for mould spots.

case story: large swedish dairy

Better work environment and fewer sick leaves thanks to new Vision System

"We absolutely did not want to compromise on quality, and the technology needed to perform as good an inspection of the cheeses as our employees did before. But the biggest and most important difference is that we have achieved a better work environment."

Download Cheese Inspection Brochure