CASE STORY

Heemskerk fresh and easy

Setting The Bar High For Quality And Efficiency

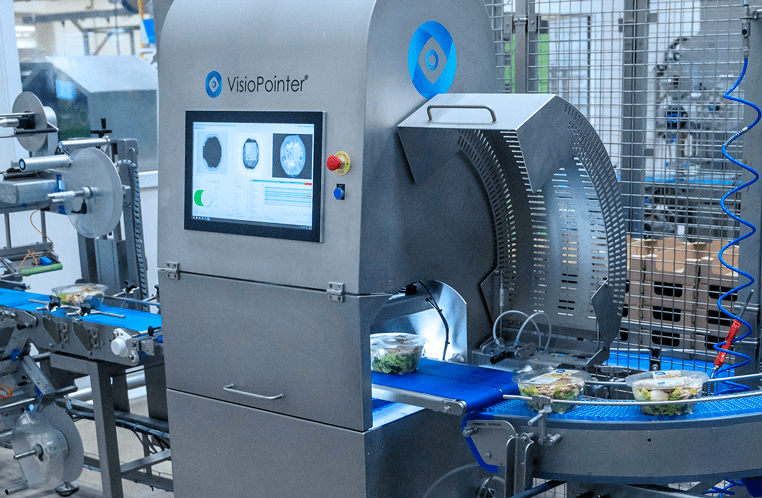

Heemskerk fresh & easy is an international provider of fresh plant-based convenience food products - delivering more than 3.5 million products every week. This is the story about how the Company uses TriVision’s VisioPointer® to ensure quality and increase efficiency.

Heemskerk wanted to automate its packaging inspection - to consistently ensure the quality of all aspects of the packaging and to increase efficiency. This aspiration turned into a strong collaboration between Heemskerk as an innovative food producer and TriVision as supplier of the vision solution.

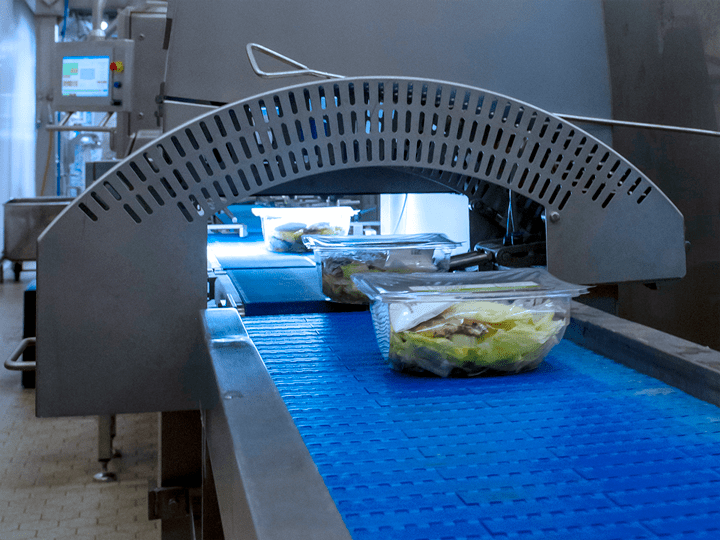

One of the inspection requirements was to detect trays with leakages - including those without visible contaminations in the package seal. As the majority of Heemskerk’s products are packed in modified atmosphere, Heemskerk was determined to detect all leakages to ensure optimal shelf life.

Additionally, Heemskerk also wanted to increase production efficiency by increasing production speed, which required an automation of inspection processes. The employees carried out important visual checks in the packaging process to ensure correct labelling, an accurate best-before date, and proper package seals.

To automate these inspections, a reliable, efficient inline vision solution had to be implemented.

Ensuring Fresh Salads and Compliance with VisioPointer®

TriVision’s VisioPointer® met the high requirements and run today in five packaging lines - inspecting 70 packages of salads, cut fruit & vegetables per minute. TriVision’s leading image recognition software provides a reliable, unmatched seal inspection and recognition, meaning both leakages with and without visible contaminations are detected.

VisioPointer® also consistently ensures accurate inspections of labels and printed date markings, rejecting errors that could be overlooked by human eyes. The inspection data is presented in a way that brings a great overview of the production performance:

“The system has a clear display on which the operator can easily see where problems are occurring in the line using green and red scales. The ease of use and the clear overview for the operator are a huge advantage compared to similar machines”, says Peter Van Kampen, Project Manager at Heemskerk.

The systems efficiently ensure consistent quality by validating Heemskerk’s packaging - ensuring optimal shelf life, food safety and perfect appearance, preventing expensive recall costs and food safety issues. For Heemskerk, the purchase of TriVision’s VisioPointer® is an investment for the future.

The VisioPointer®

is an investment for the future

The system has a clear display on which the operator can easily see where problems are occurring in the line using green and red scales. The ease of use and the clear overview for the operator are a huge advantage compared to similar machines

Peter Van Kampen

Project Manager at Heemskerk

Key Benefits

- Increased efficiency with automated quality control inspecting 70 trays per minut

- Consistent high quality - Reliable validation of all trays' seals, labelling and printed date markings

- Clear production overview - User-friendly overview facilitating easy error detection and trend spotting