Knowledge Center

Trends and Preferences in the Food Industry

The two dominating trends

Technology and sustainability are the key forces transforming the food industry in terms of production, distribution, and consumption.

The industry’s demand for greater efficiency, innovation, and transparency drives the increasing implementation of automation and advanced technologies such as AI, blockchain, and IoT applications. Consequently, ‘dark factories’ also known as ‘lights-out factories’, which operate with minimal or no human intervention, are becoming more common.

The EU legislation known as The Corporate Sustainability Reporting Directive (CSRD) ensures dedication to sustainability by establishing it as a key performance indicator (KPI) for businesses. In other words, companies must now showcase their commitment to Sustainable Development Goals (SDGs) and include in their annual reports which actions have been taken to uphold this commitment.

These implementations not only streamline production processes but also offer consumers valuable insights into the entire journey from farm to fork, hence meeting the demand for more transparency.

Retailer preferences

Retailers are becoming more stringent when selecting suppliers and for good reasons. The food industry is adopting higher food safety standards due to increasing consumer demand for higher-quality food products and tighter national laws and regulations.

For example, The BRCGS Global Food Safety Standard, which provides a framework for ensuring product safety, legality, and quality, is a highly regarded certification that retailers often require food producers to maintain.

Keeping this in mind, automating the inspection process using vision technology, thereby fully automating production and packaging lines, can be a key factor in becoming a preferred supplier to retailers. Ensured product quality protects a retailer’s brand and sales, therefore food producers that offer reliable automated processes for preventing non-compliant products from reaching supermarket shelves are very appealing to retailers.

How do you meet (and exceed) retailer demands?

Vision inspection systems using cameras and sensors to reliably inspect food products will enable producers to provide product quality guarantees and documentation, which are exactly what retailers are looking for. Naturally, this allows food producers to gain an edge over retailers when sitting at the negotiating table. TriVision offers vision solutions with a unique combination of seal and label inspection, which means that the two very common mistakes of label and seal errors can be avoided using a single vision system.

Read the case story below to gain a deeper understanding of how the unique combination of seal and label inspection can benefit your production. Vision inspection systems using cameras and sensors to reliably inspect food products will enable producers to provide product quality guarantees and documentation, which are exactly what retailers are looking for. Naturally, this allows food producers to gain an edge over retailers when sitting at the negotiating table.

Packaging Inspection

A common, yet crucial mistake is incorrect labelling. Regulations demand correct food labelling and highlighting of allergens to ensure food safety.

TriVision has several solutions for packaging inspection, covering not only label inspection, but also e.g., seal validation and verification of print.

Food Inspection

Foreign objects in the surface of food products or incorrect colour, shape and size are common errors in various food products that compromise product quality.

We help producers in multiple sectors to ensure the quality of the food product itself.

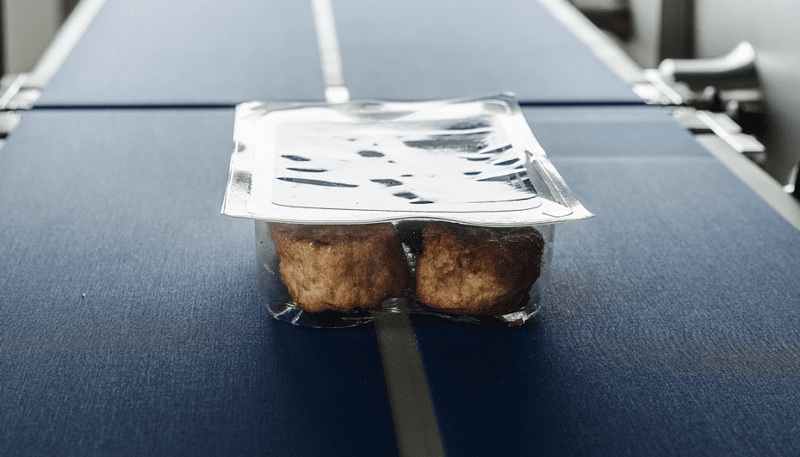

case story: Heemskerk fresh and easy

Setting The Bar High For Quality And Efficiency

Heemskerk wanted to automate its packaging inspection to consistently ensure the quality of all packaging aspects and enhance OEE. Therefore, Heemskerk chose to implement TriVision’s VisioPointer®. We interviewed Peter Van Kampen, the project manager at Heemskerk, about their new investment.