Knowledge Center

Adapting to the New EU Packaging Regulations (PPWR)

New Requirements Driving Change in the Packaging Sector

The Packaging and Packaging Waste Regulation (PPWR), which came into force on February 11, 2025, marks a significant shift for the European packaging industry.

As sustainability and circular economy goals grow more ambitious, companies in the packaging sector must adapt to stricter requirements on recyclability, material usage, and waste reduction. The PPWR is a great example of higher standards and expectations in the European packaging industry.

The PPWR regulation aims to:

- Minimize packaging waste by promoting reuse and refill systems and eliminating unnecessary packaging.

- Ensure all packaging is recyclable by 2030, meaning materials must be designed for effective reprocessing.

- Increase the use of recycled plastics, with mandatory minimum recycled content targets for 2030 and 2040.

- Reduce reliance on virgin raw materials, meaning natural resources that have not been previously processed, helping the industry transition toward climate neutrality by 2050.

Ensuring Consumer Safety and Environmental Sustainability

Beyond material-related targets, PPWR introduces specific restrictions on packaging weight, volume, and the use of hazardous substances such as PFAS, ensuring consumer safety and environmental sustainability.

Manufacturers in the European packaging industry have until August 12, 2026, to comply with these new requirements - a tight deadline that requires immediate action.

How can TriVision help the Industry to Ensure Compliance?

For packaging manufacturers, achieving compliance will involve redesigning packaging solutions, optimizing materials, and implementing advanced quality control processes. One of the most critical aspects of this transition is ensuring that packaging meets recyclability standards and contains the required levels of recycled material without compromising product safety and performance.

This is where TriVision can assist with proven technology and automation that can become invaluable. High-precision automated inspection systems will be key to helping manufacturers detect non-compliant packaging and optimize production processes to comply with the PPWR regulation by August next year.

Supporting the Industry with Advanced Vision Inspection Systems

As a leading provider of vision inspection solutions, TriVision offers cutting-edge technology designed to help packaging manufacturers comply with regulations, including the new EU requirements.

When adapting to new demands from both the EU and consumers, companies have different paths to explore. Standard vision inspection systems often struggle to detect seal contamination, particularly when the packaging film is non-transparent or when there is a very low contrast between the contaminant and the film material.

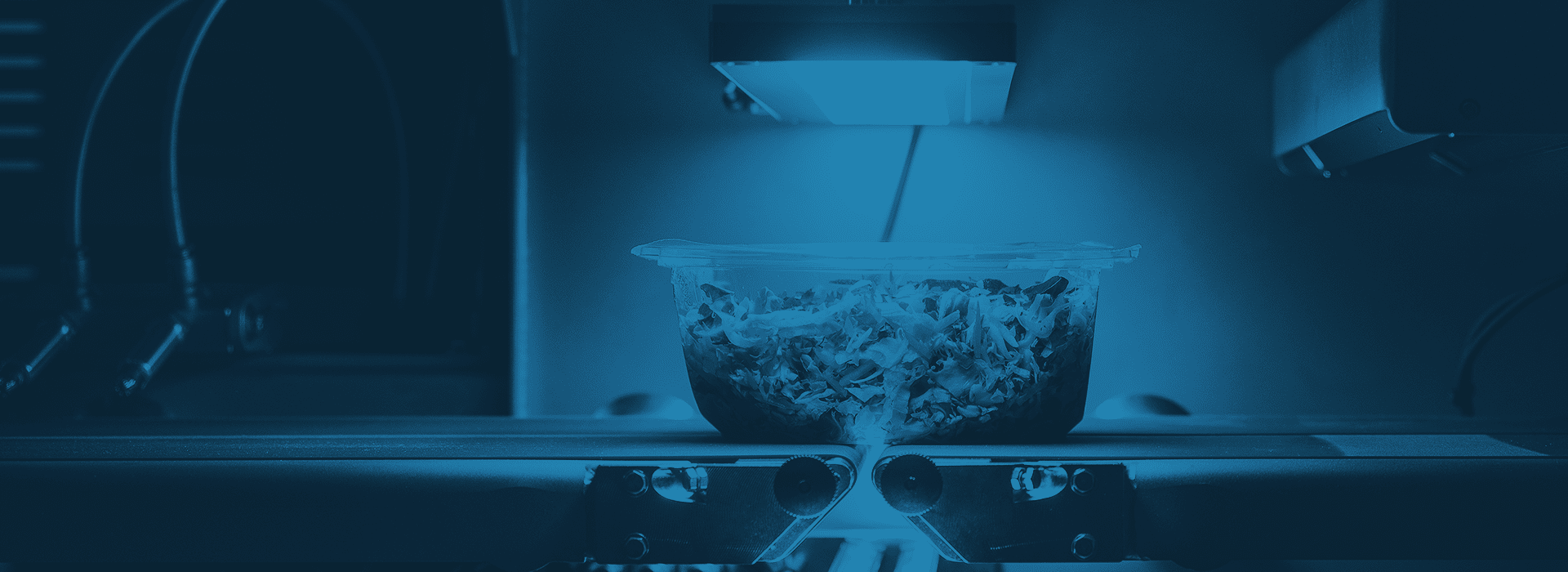

Some manufacturers have started using thinner plastic film for their packages to reduce the amount of raw material as well as the weight of the packages. Another transition in the industry that we have noticed is the shift from plastics to non-transparent paperboard trays, pots, and containers. These changes could result in challenges when it comes to detecting contamination in the seal area.

TriVision’s latest innovation - the HyperPointer®, is designed for reliable and consistent quality control of non-transparent packaging, including plastic and paperboard trays, pots, and containers. Utilizing hyperspectral imaging, the system accurately detects contamination in the seal area across various types of packaging.

TriVision’s automated inspection systems help ensure..

Packaging Quality: TriVision's systems perform comprehensive inspections of seals, labels, prints, and barcodes, ensuring that packaging meets stringent quality standards and is free from defects. This aligns with the PPWR's emphasis on minimizing packaging waste and enhancing recyclability.

Reliable Quality Control: By automating the inspection process, TriVision reduces reliance on manual labor, increasing inspection accuracy and consistency. This automation supports compliance with PPWR requirements by ensuring that all products are inspected thoroughly and efficiently.

Optimization through Production Intelligence: TriVision's solutions offer detailed production statistics and insights, enabling manufacturers to monitor performance, identify areas for improvement, and make data-driven decisions. This helps manufacturers optimize processes to meet the PPWR's goals of waste reduction and sustainability.

By integrating advanced vision inspection and automation solutions, packaging manufacturers can streamline their production processes, avoid compliance risks, and future-proof their operations in an industry with increasingly stringent requirements.

The Time to Act Is Now

With the PPWR application date set for August 12, 2026, companies must start planning and implementing compliance strategies today. By investing in advanced inspection technologies, manufacturers in the packaging industry can navigate these regulatory changes effectively - ensuring sustainability, efficiency, and market competitiveness.

At TriVision we are committed to supporting the industry with the tools and expertise needed to meet these new challenges. Our HyperPointer® overcomes challenges by ensuring consistent and precise inspection, regardless of the packaging material, layout, or size - providing a superior solution where standard vision systems fall short.

Contact us today to learn more about how our vision inspection systems can help you stay ahead of regulations and secure a sustainable future for your packaging solutions.