IML Inspection

IML Inspection

Quality Inspection

Of IML Containers

IML packaging i.e., plastic cups, buckets and other plastic packaging containing in-mold labels, meaning the label is embedded in the package’s composition, is widely used across food sectors.

During the production, various incidents can cause structural defects in the plastic containers, which can result in poor end-user perception and product recalls if the defective products are not detected and rejected.

Vision Inspection of IML Packaging

Let Only Perfectly Molded Cups Leave The Factory

During the manufacturing process, a number of structural defects may occur in the produced containers and compromise the quality of the containers.

By inspecting IML cups' structure and surface, we are able to detect:

- Overmould errors, which can cause leakages

- Dosing errors - if too little or too much material is in the container, which shows on the edge of the container.

IML Inspection solutions

IML-Inspector®

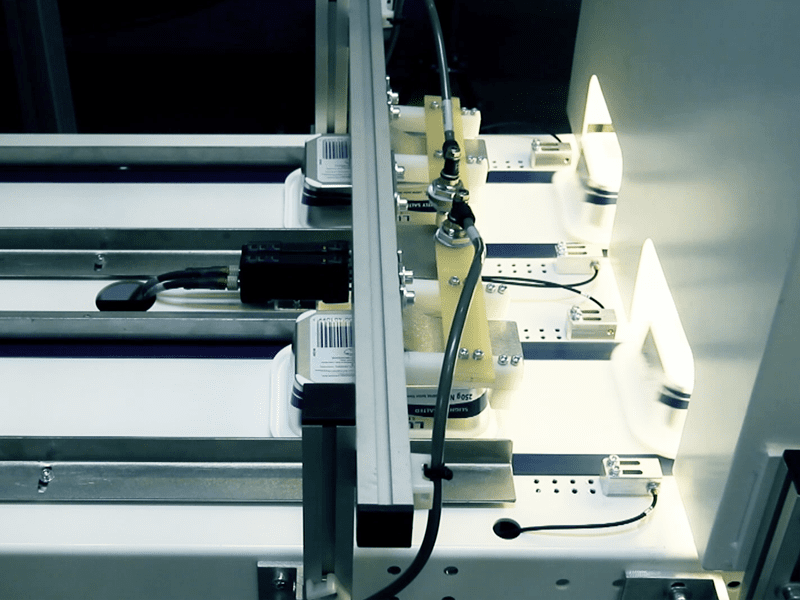

TriVision's IML-Inspector® provides a solution for producers of different IML containers with multiple configurations, providing efficient inspection, validation, and documentation of IML containers' quality - while facilitating production optimization.