Seafood

Seafood

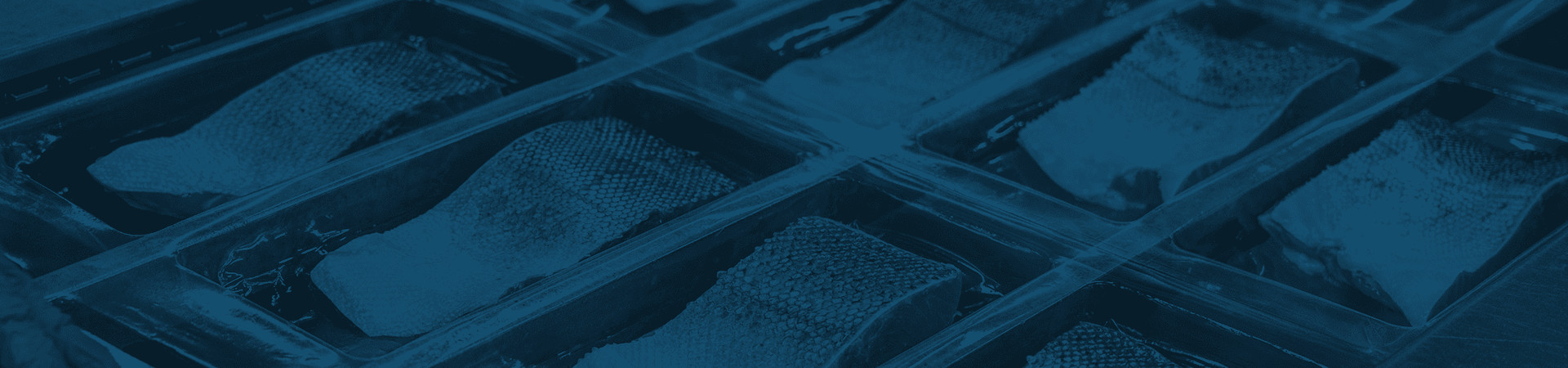

Inspection of Seafood

And Its Packaging

Many details matter within Seafood products when it comes to delivering high quality products. Multiple characteristics of the raw fish and its packaging are important to inspect.

We provide vision inspection solutions for validating the quality of seafood products, supporting production processes and for ensuring proper packaging and hence food safety.

Automated Packaging Inspection

Preserved Seafood And

Ensured Food Safety

Ensuring properly sealed packaging for Fish products such as salmon or mackerel it not just important for preserving a premium product quality. It is also crucial for avoiding contamination and spoilage of the fish to ensure food safety for consumers. Additionally, the food labelling must also be correct for multiple purposes.

Our vision inspection solutions inspect the typical types of packaging used by the seafood manufacturing industry such as club cans and thermoformed packaging – to ensure perfect packaging and hence a perfect product and ensured food safety.

Colour Inspection

Inspection of Fish Fillets

The colour of a fish's flesh tells lot about its quality, which is why seafood manufacturers want to determine the quality of e.g. salmon fillets by inspecting the flesh's colour.

By inspecting and analyzing the colour of fillets, our solutions enable manufacturers to categorize, sort and reject fish according to the quality.

Orientation Check

Ensure Proper Processing

Automated processing lines require that incoming fish have a specific orientation. Incorret orientation can cause incorrect processing, spoiled products and in worst cases downtime.

By inspecting the orientation of incoming fish, our solutions help seafood manufacturers ensuring proper processing.

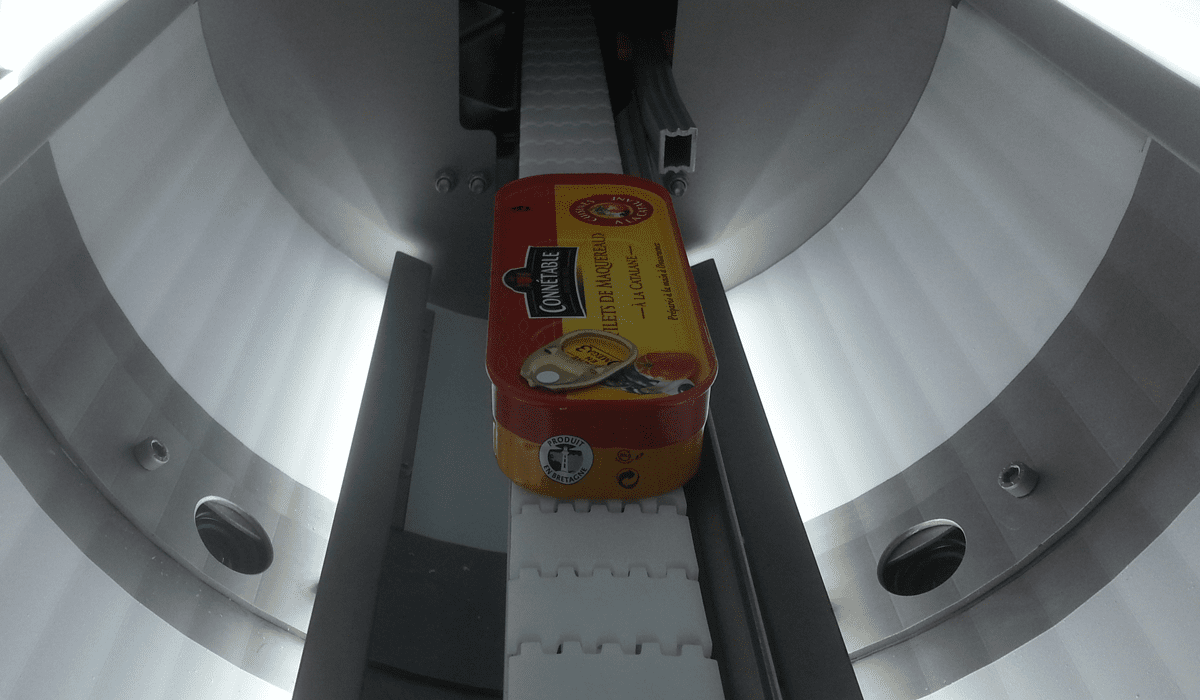

Case Study

Saeby Fish Canners Ltd.

Europe's largest producer of canned mackerel has automated their packaging inspection by implementing TriVision Solutions. Discover all the achieved benefits by reading our case story,