Meat

Meat Industry

Inspection Solutions

For Any Meat Production

Different priorities exist across different meat productions. We provide solutions for product and packaging inspection within production lines for cold cuts or fresh meat.

Our Solutions also help producers of meat products to optimize quality, production and ensure traceability.

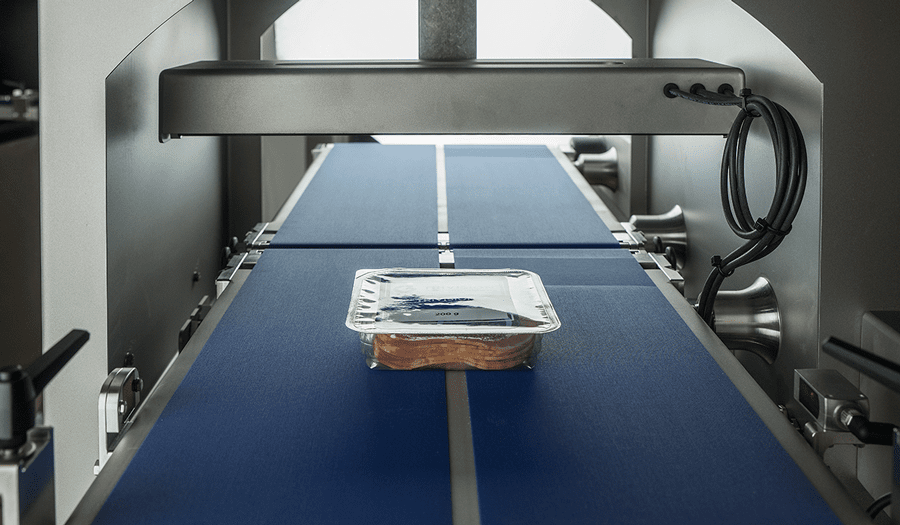

Quality Control of Meat Packaging

Ensure Intact, Traceable

Meat Packaging

Vision Inspection of meat packaging enables manufacturers to ensure that packages are properly sealed and traceable, by inspecting and validating package seals and the food labelling.

COLOUR INSPECTION

Inspect Meat's Colour

To Ensure Product Quality

We develop solutions that inspect the colour and hence quality of different meat products. Blood spots occurring in fresh meat products is not uncommon, but unappealing, and cartilage and fat will also be present, but the amount defines the quality. Finally, precooked products such as bacon can be inspected to ensure that each product has been cooked correctly.

By inspecting the colour of different meat products, TriVision solutions detect those that do not meet the set quality standards. All products having too high amounts of blood spots, cartilage or fat, or incorrect colour due to under or overcooking are detected and rejected.

Slice Inspection

Ensuring Proper Stacking

And Packing of Sliced Meat

Checking the position and shape of meat products is crucial to facilitate accurate stacking and in the end a successful packaging process. If meat slices do not fit into their container, the result will be poorly packed products and in worst cases food contamination in the package seal when welded.

We ensure the size and shape of sliced meat products such as cold cuts, bacon and burger patties before they are stacked.