Knowledge Center

How to Avoid Food Safety Incidents:

Detecting Contaminated Meat and Dairy Products

Food safety: prepare for the unexpected

In honor of World Food Safety Day, which was June 7, this article focuses on food safety in the meat and dairy industry. World Food Safety Day creates awareness about the risks of food contamination and emphasizes the importance of ensuring food safety through the entire food production process, aiming to prevent diseases caused by consuming contaminated food. The Theme of World Food Safety Day 2024 is dedicated to the importance of preparing for food safety incidents, in other words, preparing for incidents where consuming food poses a health risk.

"One in ten people worldwide fall ill from contaminated food each year" - WHO, 2024

According to WHO, every year, one in ten people worldwide suffers from illness due to contaminated food, and 40% of these are children under 5 years old. One potential cause of a food safety incident is inadequate quality control in the production facilities. Without a top-notch inspection process, producers risk failing to detect contaminated food before it reaches the supermarket shelves, which can have severe consequences.

Meat contamination

Meat products are great nutrition sources, but they are also great at causing bacteria growth, which may lead to food safety incidents. Some bacteria are more dangerous than others, and research in food contamination has primarily focused on pathogens transmitted through food, and not so much on spoilage organisms, which are typically less dangerous.

The main difference between the two is that the consumption of food with pathogen contamination can cause serious diseases, while the consumption of food with spoilage organisms typically does not cause diseases. However, spoilage organisms can reduce product quality and shelf life, leading to extensive economic losses, which is why it should not be overlooked. Additionally, in food processing plants, pathogens and spoilage organisms coexist and affect each other, thereby understanding both is crucial to attain a more sustainable and safe food industry.

Meat products obtain spoilage organisms in the processing stages more often than from animals or humans. Luckily, these spoilage organisms are often visible/detactable through, for instance, color changes. Besides checking for color changes, checking the position and shape of meat products is important for a successful packaging process. For example, if meat slices do not fit into their container, you will risk food contamination in the package seal when welded.

Dairy contamination

As with meat production, cheese production involves numerous challenges that can compromise the final product. Cheese products must contain the right kind and the right amount of mold, and therefore it is important for cheese producers to meticulously oversee the entire cheese-making and aging process. During ripening, mold spots may occur in cheese blocks if oxygen is trapped under the plastic, or if there is moisture or the temperature is too high.

Spoilage organisms like the wrong kinds of mold, or foreign objects such as plastic are often visible and can be detected with the human eye. However, unlike the human eye, automated vision inspection does not grow tired, and can inspect cheese products much quicker and more efficiently. This brings us to the solutions for the problem of contaminated food and potential food incidents...

Solutions?

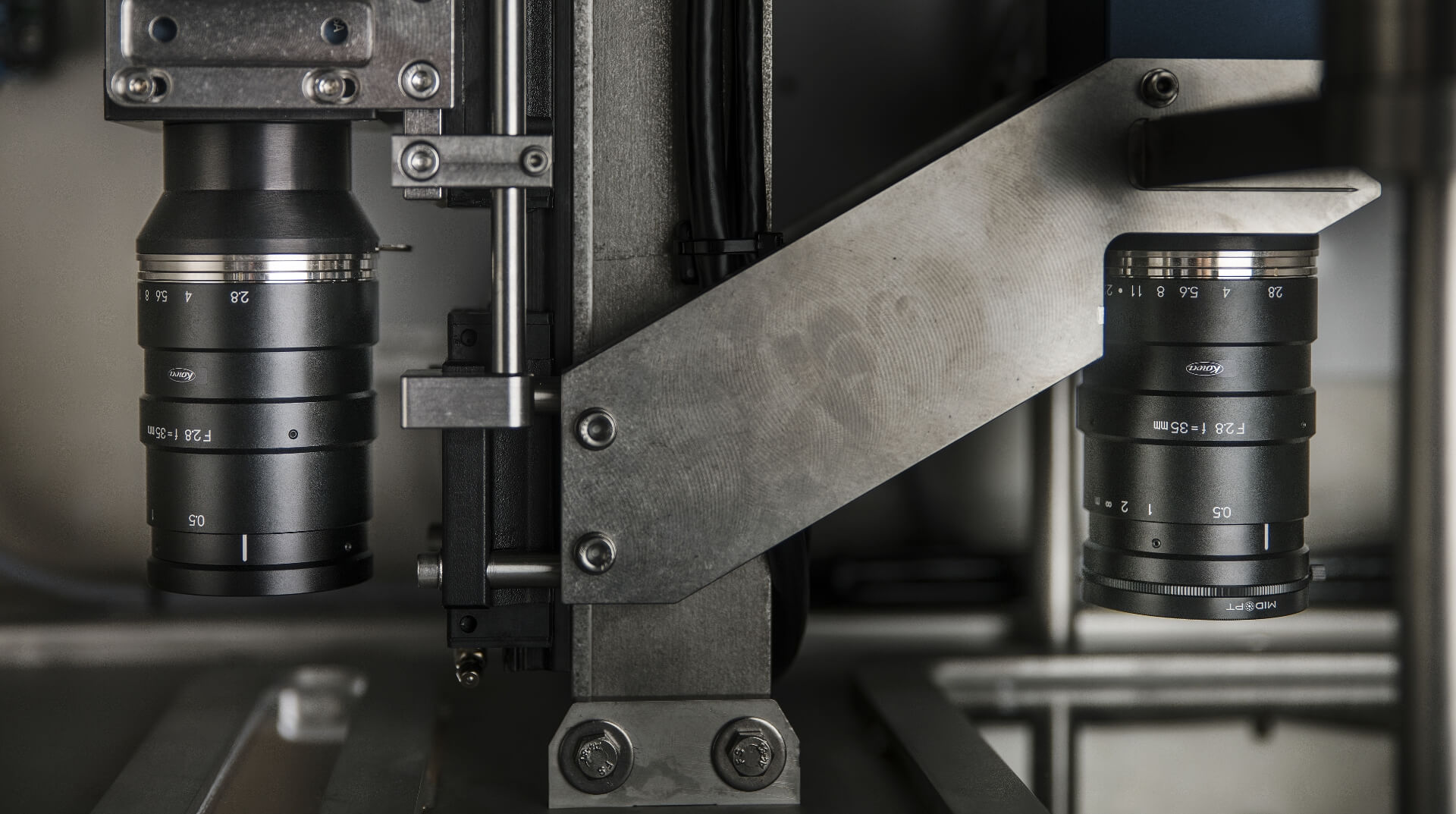

One effective solution for avoiding food incidents is improved quality control with the help of automated inspection processes. With decades of experience in developing efficient inspection systems, TriVison provides a wide range of solutions that detect anything from mold on cheese blocks, blood spots on fresh meat, seal contamination of food packaging, etc.

When vision experts at TriVision identify a specific need in the industry, we develop new solutions to address this need. Essentially, we spend a lot of time on research and development. For example, we recognized the need for quality control of large cheese blocks, which may contain mold spots or plastic contamination after the foil removal process, and this led to the development of the CheeseInspector®.

A wide range of solutions

VisioPointer®

for the most thorough inspection

VisioCompact®

stand-alone solution

360 Inspector®

designed to inspect round bottles, cans, and jars

VisioLine®

for integration into thermoformers

VisioOne®

for essential packaging applications

SmartInspector®

within a minimal footprint

CheeseInspector® Rectangular

for inspection of rectangular cheese blocks