CASE STORY

Large Swedish Dairy

Better work environment and fewer sick leaves thanks to new Vision System at a large dairy in Sweden

The primary goals of the dairy are to strengthen the conditions for a sustainable milk production in the northern region and to meet the demand for fresh, locally produced dairy products of high quality from consumers and customers.

As a central dairy player in Sweden, they do everything a dairy usually does here, from various types of milk, yogurt, and fermented milk products, which are also sold in other parts of Sweden. They also produce cheese such as Herrgård, Präst, and Grevé, among others.

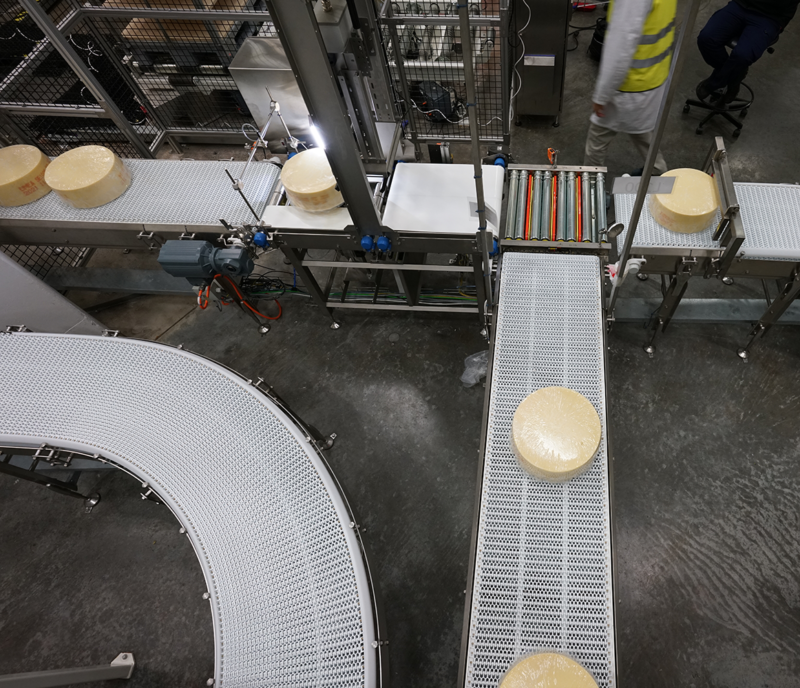

The dairy also manufactures a legendary bestseller that challenges Italian Parmesan cheese as a flavor-enhancing cooking cheese. A whole block of this cheese weighs a full 18 kg, and these culinary heavyweights are one of several cheese varieties that pass through the two newly installed production lines with vision systems from TriVision.

A better work environment thanks to the new vision system

"We absolutely did not want to compromise on quality, and the technology needed to perform as good an inspection of the cheeses as our employees did before. But the biggest and most important difference is that we have achieved a better work environment."

Production technician

Large Swedish Dairy

Why was there a need to invest in new equipment?

- "We previously had manual inspection of the cheeses before they went on to cheese refinement, with two lines and two employees responsible for each line. Since the volumes are so large and the cheese blocks are so big and heavy to work with, we simply wanted to eliminate the manual handling," states the production technician.

What was important for you before the investment?

- "We absolutely did not want to compromise on quality, and the technology needed to perform as good an inspection of the cheeses as our employees did before."

Why did you choose TriVision?

- "TriVision had a ready system for our purpose, while the others only had prototypes, more or less. That was important to us."

What is the major difference now that you have had the system in operation for a while?

- "The biggest and most important difference is that thanks to the new vision system, we have achieved a better work environment. The employees who previously performed manual quality control of the cheese are still with the company, so there have been no reductions in personnel costs in this case," he continues:

- "However, the system has saved valuable shoulders and backs, and sick leaves have decreased, which is very gratifying. A large round cheese weighs 18 kg, and now the staff no longer must lift and turn the cheeses to look for mold spots and other deviations. This really must mean that we have made an important and good investment," concludes the dairy's production technician.

100 tons of cheese per week

In total, around 100 tons of cheese per week are inspected using advanced camera technology to detect mold and other visible damages and deviations before the cheese moves on to cheese refinement

Production technician

Large Swedish Dairy

COMPLETE SURFACE INSPECTION

About the CheeseInspector® Vision System

The equipment consists of two vision stations in the flow of large cheese blocks. At both stations, there is a robot (from the dairy) that places the cheeses onto a conveyor belt. The cheeses are then transported one by one into the CheeseInspector®. There, the cheese is lifted and rotated while three different cameras inspect the cheese.

The cheeses are inspected on the underside, the side, and the top. They then exit the CheeseInspector®, and based on the inspection results, the correct cheeses continue in the regular flow, while those needing further inspection are redirected to another flow. Everything is controlled via a control panel (industrial PC), where images are also stored for later analysis.

Download Cheese Inspection Brochure