CASE STORY

Colruyt Group

VisioPointer® streamlines the production lines

Colruyt Group is a Belgian family business that grew from a local wholesaler in 1928 into a family of companies. The company has more than 600 supermarkets for food and non-food in Belgium, France, and Luxembourg. Additionally, it has several production activities in several industries such as cheese, coffee, wine, meat and salad spreads and is active in export, technology and automation.

Automation is also implemented in their own production lines. This also applies to the production lines for salad spreads, where robots now are packing salad jars into boxes. Due to automatization eliminating all manual actions, manual inspection needed to be replaced as well. To do so, Colruyt Group implemented TriVision’s VisioPointer®.

“The VisioPointer® makes it possible to produce faster while increasing and ensuring quality at the same time.”

Tim Noppen

Solution Analyst at Colruyt Group

Ensured quality and faster production

Tim Noppen, Solution Analyst at Colruyt Group, explains the VisioPointer®’s impact: 'Not only in the salad production line, but also in e.g. the cheese factory, there are repetitive actions. When we let robots take over, employees are released from these tasks, allowing them to take on more value-adding tasks. Also, the salad spread production line has a very high speed - 120 jars per minute roll off the belt. It's impossible for an employee to check jar by jar at this speed, but the VisioPointer® can. And what's more, much more can be checked as a result.'

The VisioPointer® takes a photo of each jar passing through the system with both its top, bottom and side camera. All cameras check label presence, label ID, margins as well as barcode and print ID and quality. If any label or information is missing or incorrect, or if margins or print quality does not match the set parameters on a jar, it will be ejected from the production line and end up in a separate container. The operator will then visually check whether the error on jar can be corrected or not, and perform a root cause analysis and optimize.

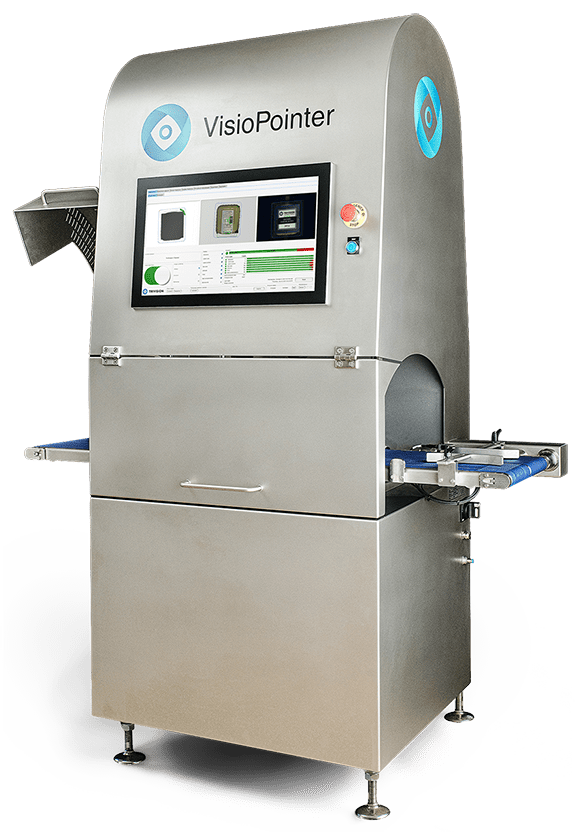

VisioPointer®

A Turnkey Vision Solution for Thorough Packaging Inspection

VisioPointer® is a high-end, state-of-the-art vision inspection system designed for thorough quality control of food packaging.

With three built-in cameras, conveyor belt, ejector mechanism and operator panel in its compact body, VisioPointer® is a turnkey solution easy to implement in most food packaging lines.