Barcode Inspection

Barcode Inspection

Facilitate Efficient Processes with Barcode Inspection

Having accurate and readable barcodes on packaging are essential for manufacturers to operate efficiently. Barcodes of the right quality are key to inventory management, track and trace, and product handling throughout the supply chain.

TriVision solutions guarantee that all approved packages feature correct and readable barcodes, including verification of barcode grading and quality.

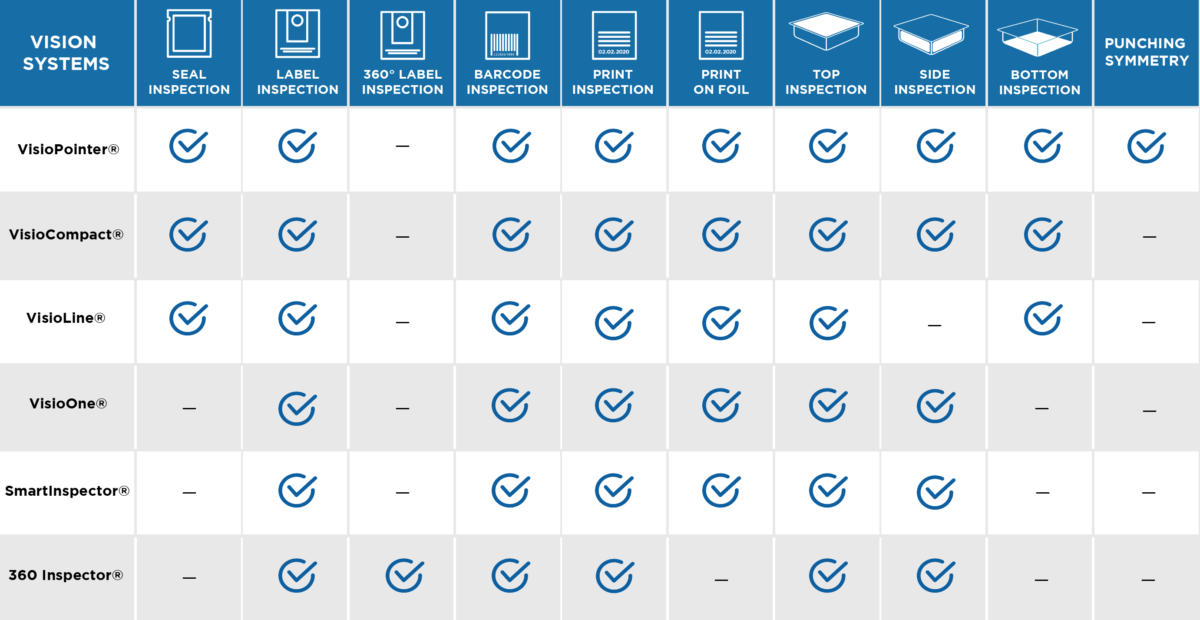

Solutions for Barcode Inspection

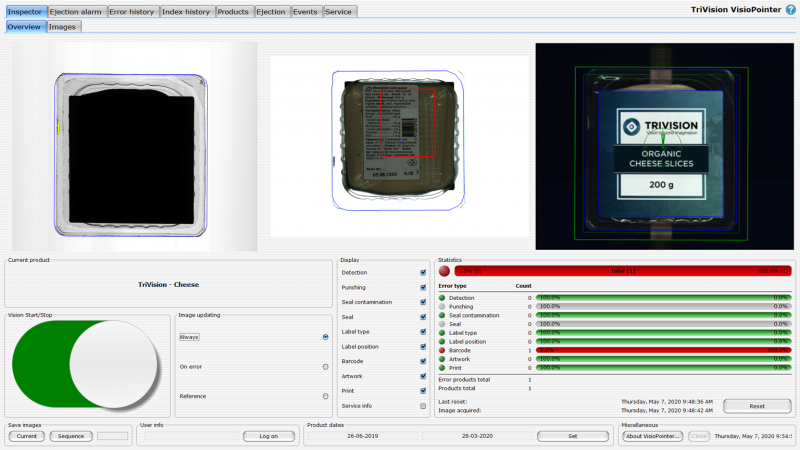

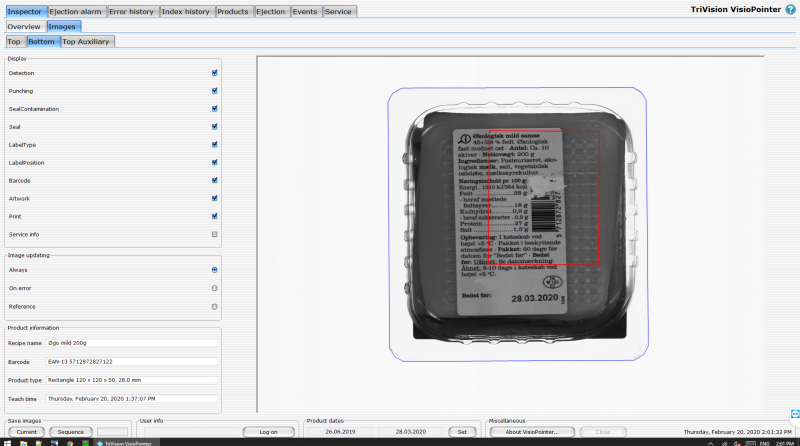

VisioPointer®

for the most thorough inspection

VisioCompact®

stand-alone solution

VisioLine®

for integration into thermoformers

SmartInspector®

within a minimal footprint

VisioOne®

for essential packaging applications

360 Inspector®

designed to inspect round bottles, cans, and jars

Missing Barcode

Missing Barcode

DIFFERENT TYPES OF BARCODES

Inspect Different

Barcode Types

There are several types of barcodes in the food and pharma industries. In the food industry for example, 1D barcodes count EAN-8 and EAN-13 barcodes, and QR codes count QR and Data Matrix codes.

1D barcodes contain static information like country of origin, production site, and batch number, while others carry dynamic data such as weight or price.

Our vision software allows us to inspect, read, and verify all types of barcodes, ensuring that every barcode:

- Are accurate and contain the correct information

- Are readable and have the correct grading and quality

PACKAGING INSPECTION SOLUTIONS

A Range of

Plug-and-Play Solutions

TriVision’s standardized Plug-and-Play solutions for packaging inspection are all built upon the same leading technology and software.

TriVision's various vision systems offer tailored solutions to meet the specific needs of different types of packaging lines and inspection requirements.