Packaging Inspection

Vision-Based Packaging Inspection

Automate Packaging Inspection

to Meet Stringent Requirements

The quality of packaging, whether it is food packaging or pharma packaging, greatly influences quality, safety, compliance, and the efficiency of supply chain processes. Numerous types of packaging are used for products in the food and pharma industries, but they typically all share the same purpose of preserving the product, providing correct product information, making the product appealing, and ensuring efficient processes during the supply chain journey.

We provide vision inspection solutions for quality control of various types of packaging, enabling manufacturers across sectors to inspect their packaging and make sure it meets the desired quality level. By automating the packaging inspection, ensuring packaging quality, and utilizing quality data for production optimization, we help maximize manufacturers’ production performance in multiple ways. TriVision solutions help increase throughput, reduce manual labour, facilitate customer loyalty, and eliminate expensive recalls and fines. Additionally, our systems reduce food loss and waste, rework, and downtime.

PACKAGING INSPECTION SOLUTIONS

A Range of Plug-and-Play Solutions

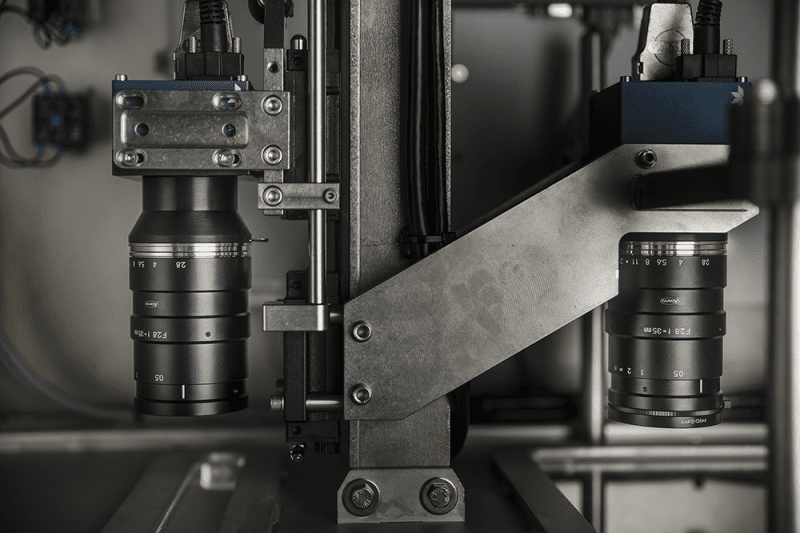

TriVision’s standardized Plug-and-Play solutions for packaging inspection are all built upon the same leading technology and software.

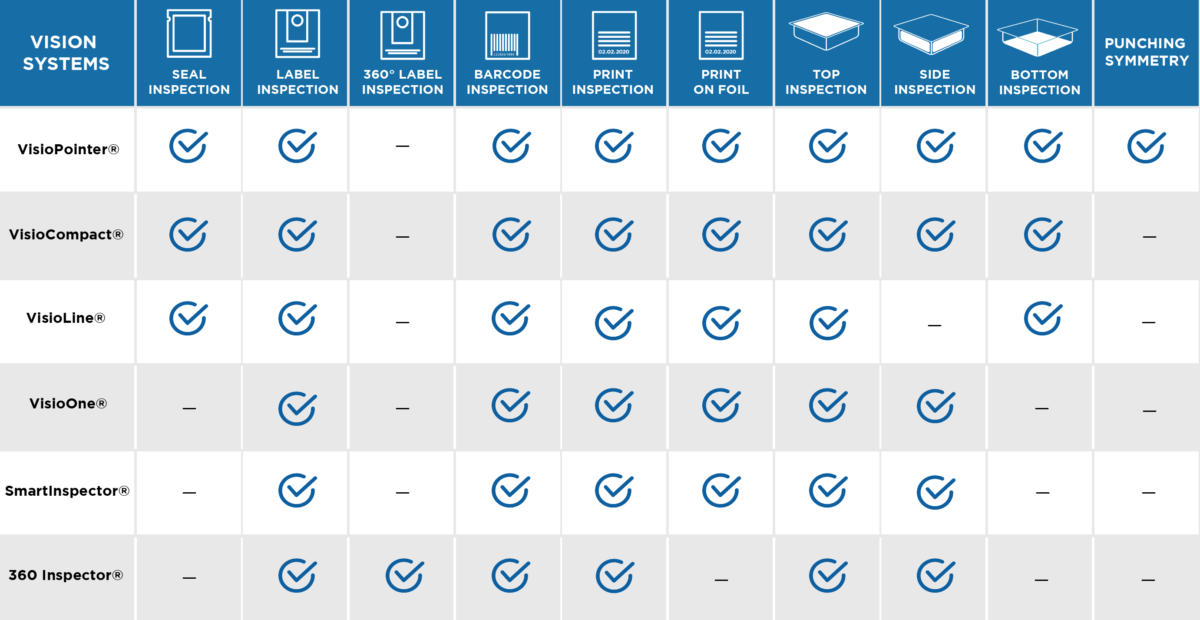

TriVision's various vision systems offer tailored solutions to meet the specific needs of different types of packaging lines and inspection requirements.

Solutions for Packaging Inspection

VisioPointer®

for the most thorough inspection

VisioCompact®

stand-alone solution

VisioLine®

for integration into thermoformers

SmartInspector®

within a minimal footprint

VisioOne®

for essential packaging applications

360 Inspector®

designed to inspect round bottles, cans, and jars

Case study

Heemskerk fresh and easy

Discover how Heemskerk fresh and easy utilizes TriVision solutions to ensure superior packaging quality and efficient production processes.

Numerous Inspection Types

Available in different configurations with seal, label and artwork, print and barcodes inspection as well as top, bottom and side inspection.

Turnkey

Vision Solutions

TriVision offers complete solutions in one unit with sensor, camera, lights, built-in conveyor, ejector mechanism and operator panel.

Solid Production Overview

TriVision's intuitive software powers all our vision systems, which makes it easy for operators to adjust quality levels and monitor the production.

Download Product brochure

Talk to a Vision Expert

Curious about how vision inspection can boost your production?

Send us a message and we will reach out as soon as possible!