Seal Inspection

Vision-based Seal Inspection

Inspection and Verification

of Seal Integrity

Many products, both food and pharma, are packed in a closed environment with gas mixtures to prevent contamination.

In food products especially, the seal is important to ensure that the packaged product keeps it original appearance, nutrients, taste, and shelf life. For pharma products, the seal is also important to avoid damaging the product inside the packaging.

We develop vision-based solutions for efficient validation of package seals to ensure product safety and integrity.

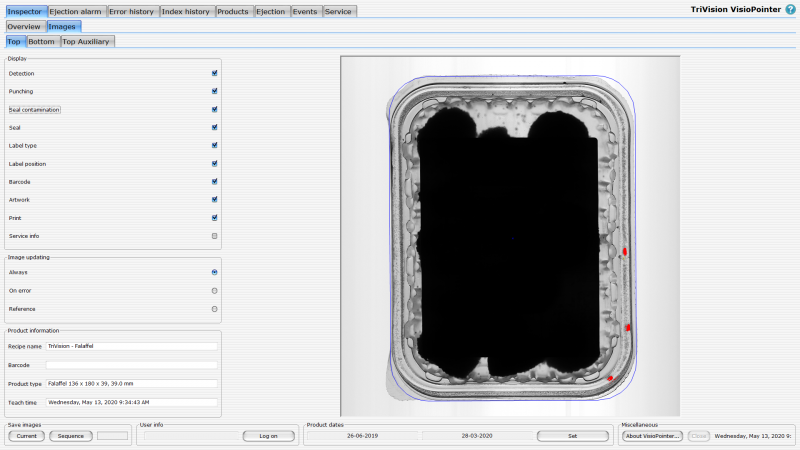

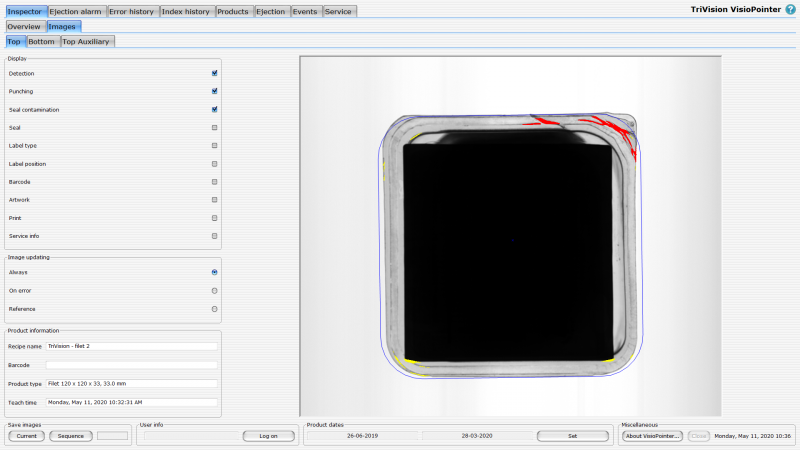

Seal Contaminations

Seal Errors

Sometimes, the topfoil wrinkles during the welding process. This can cause tunnel leakages compromising the preserving atmosphere of packages and the packaging appearance.

How TriVision Seal Inspection Works

case story: Heemskerk fresh and easy

Setting The Bar High For Quality And Efficiency

Heemskerk wanted to automate its packaging inspection to consistently ensure the quality of all packaging aspects and enhance OEE. Therefore, Heemskerk chose to implement TriVision’s VisioPointer®. We interviewed Peter Van Kampen, the project manager at Heemskerk, about their new investment.

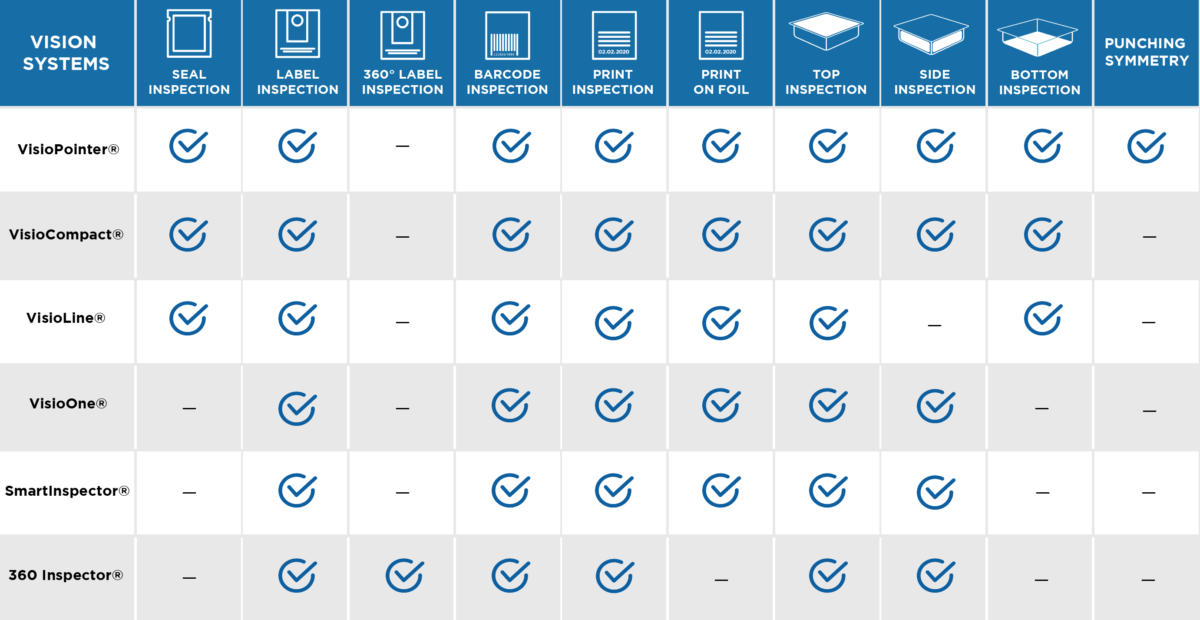

PACKAGING INSPECTION SOLUTIONS

A Range of

Plug-and-Play Solutions

TriVision’s standardized Plug-and-Play solutions for packaging inspection are all built upon the same leading technology and software.

TriVision's various vision systems offer tailored solutions to meet the specific needs of different types of packaging lines and inspection requirements.